Easy control of contamination level in cleaning and rinsing baths

Contamination in cleaning processes is costly, time consuming, and hard to quantify. ConSpector helps resolve this problem.

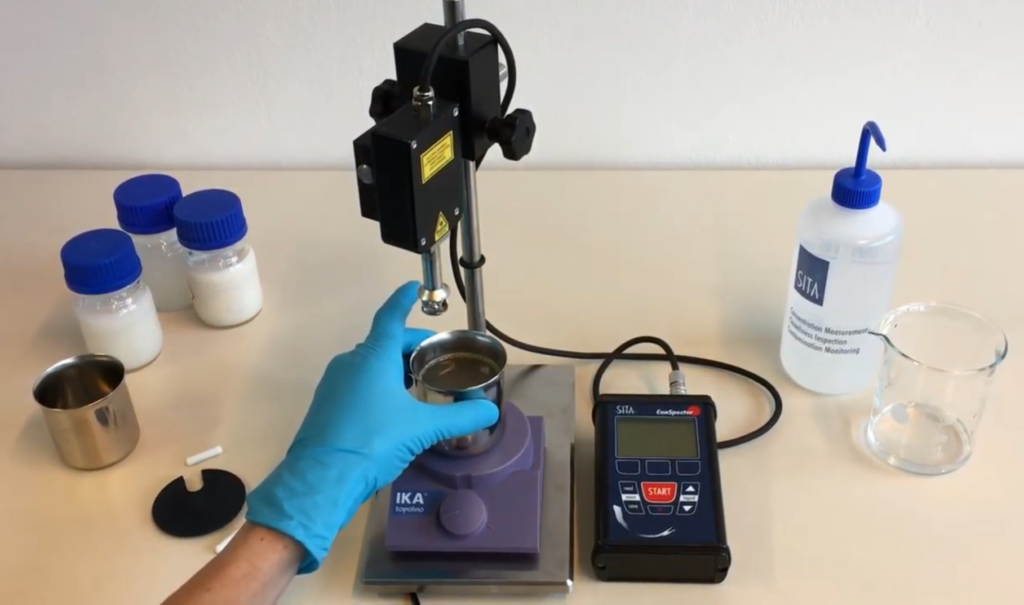

Easy to Use

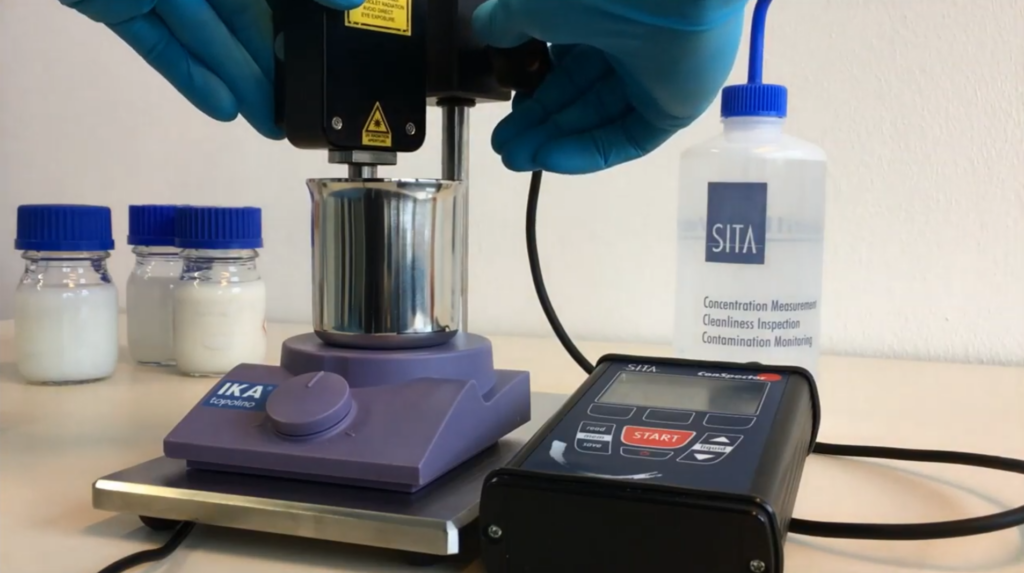

ConSpector takes minutes to setup, operate and get results with. Training is also simple, meaning operators learn to use the equipment quickly, resulting in minimal implementation time. This simplicity ensures that benefits can be seen as soon as the equipment is delivered.

Make Your Data Objective

An easy to read LCD display shows results as they are collected whilst they are also stored onboard, enabling download of results via USB at a later stage to the optional SITA ProcessLog software, providing full traceability of data.

Gone are the days of guessing cleaning bath conditions, or using trial and error. ConSpector provides a reliable method of measurement that is consistent across operators.

Get Results Quickly Where You Need Them

ConSpector is designed for use on the shop floor. With a rugged design and easy to read LCD display, it is easy to use without the need of being kept in a special environment.

Typical Applications

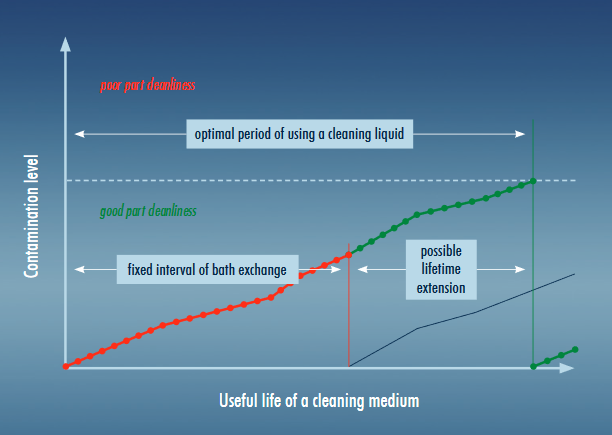

Excessive bath operation time leads to a build up of contamination from parts that have been cleaned. This can often be hard to determine, which leads to one of two scenarios:

- Cleaning solution becomes excessively contaminated, reducing its effectiveness (and potentially making it hazardous)

- Cleaning solution is too frequently changed before it is necessary because it is hard to ascertain how much life it has left. This leads to unnecessary increases in downtime and costs.

By using ConSpector to check cleaning bath conditions, it is easy to develop a clear picture of the condition and lifespan of cleaning solutions. This means that they are replaced at exactly the right time, for maximum efficiency.

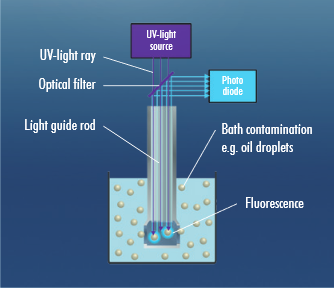

Operating Principle

Typical sources of contamination such as oil, grease and cooling lubricants fluoresce when exposed to UV light. ConSpector uses this quality to detect the levels of contamination by exposing the fluid to UV light and then detecting the level of fluorescence that is returned to the sensor. The larger the value, the greater the contamination that is detected.

Specifications

| Contamination level / Fluorescence intensity | |

| Measuring range | 1-40,000 RFU* |

| Max. measuring deviation | 0.5 % of measuring range |

| Liquid temperature | |

| Measuring range | (0-100) °C (32-212°f) |

| Max. measuring deviation | 0.5% of measuring range |

| Current Supply | |

| Mains adapter | 5 V/500 mA (USB) |

| Battery (Lion, integrated) | 3.6 V/1950 mAh |

| Max. power consumption | ~2.5 W |

| Excitation diode | 365 nm, max. 150 mW |

| Interface, Display, Memory | |

| USB interface | Data transfer, power supply & charging of battery |

| Display | LCD, 128 x 64 Pixel, illuminated |

| Memory | permanent: measuring parameter / data 255 profiles, 8191 measuring values per profile |

| Ambient conditions | |

| Acceptable ambient temperature (storage / operation) | (-20-60)°C / (10-50) °C (-4 - 140°f) / (50-122°f) |

| acceptable ambient conditions | rel. humidity< 70 %, air pressure(300...1060) hPa |

| Housing, Dimensios, Weight | |

| Housing | Aluminum, IP 51 |

| Dimensions (WxHxD) Basic Unit Sensor head |

129x82x48 in mm (5x3.2x1.9") 142x50x30 in mm (5.6x2x1.2") |

| Weight of instrument | 560 g (20 oz) |

* RFU - Relative Fluorescence Unit of SITA-Fluorescence standard