In precision manufacturing, surface preparation isn’t just a preparatory step—it’s critical to the performance, safety, and longevity of the final product. This was realized by a surface treatment company, recognized as one of the most technically advanced in aluminum powder coating and metal surface preparation, serves demanding sectors such as automotive, aerospace, medical, and even lighting.

For this organization, cleanliness is foundational. And when surface bonding, coating, or painting is involved, “clean” must be verified—not assumed.

The Challenge: Hidden Contaminants

Metal parts—particularly aluminium—often carry residual contamination from casting and machining processes. These contaminants include oils, coolants, and release agents that can inhibit proper adhesion. High-quality finishes, whether painted, powder-coated, or adhesively bonded, rely on high surface energy and contaminant-free surfaces to perform reliably in real-world applications.

This provider had used surface energy test methods such as Dyne inks to assess cleanliness. While these methods give valuable go/no-go indicators, they were seeking a more quantitative, scalable, and repeatable way to evaluate surface contamination—especially across large or complex-shaped components.

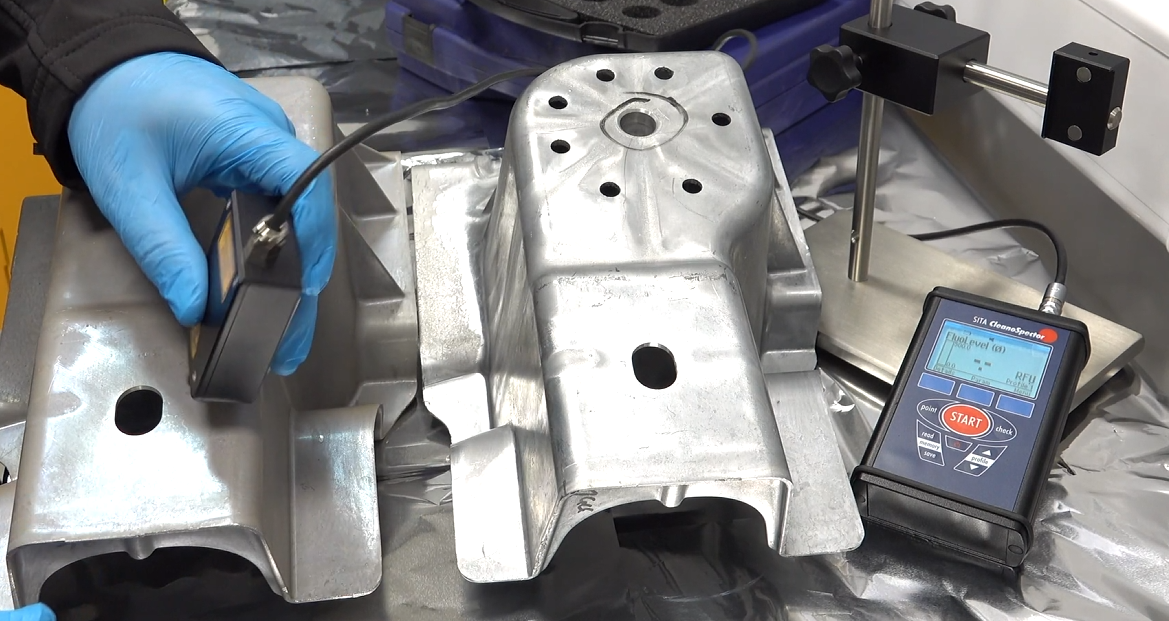

A Non-Destructive Solution: SITA CleanoSpector

To meet this need, the company turned to the SITA CleanoSpector—a handheld metal cleanliness test instrument. The CleanoSpector uses UV-induced fluorescence to detect and quantify organic contamination on metal surfaces. Metal itself does not fluoresce, but oils and residues do—allowing the instrument to provide immediate contamination readings in Relative Fluorescence Units (RFU).

This quantitative data added a new dimension to the company’s quality control process, enabling:

-

Fast testing across large surface areas

-

Repeatable, non-destructive measurements

-

Objective RFU values for trace contamination

-

Verification of part cleanliness before coating or bonding

Automotive-Ready Cleanliness for a Changing Market

One area where this tool has proven especially useful is in the automotive industry, where the shift to electric vehicles (EVs) is transforming the way components are joined. As OEMs reduce mechanical fasteners in favor of adhesive bonding, surface cleanliness becomes even more mission-critical.

This provider works to strict OEM specifications for cleanliness. The CleanoSpector helps validate that parts meet defined RFU thresholds and identifies which parts may require additional cleaning before coating or assembly. In fact, major OEMs now reference CleanoSpector RFU readings on their technical drawings—highlighting the industry’s growing reliance on measurable cleanliness.

Conclusion: When Precision Matters, So Does Surface Cleanliness

Cleanliness isn’t just a matter of appearance—it’s a measurable factor that determines whether coatings will adhere, adhesives will bond, and finished products will perform as intended. By integrating fast, non-destructive cleanliness verification into their process, advanced manufacturers can meet the exacting standards of industries that can’t afford to compromise.

With tools like the SITA CleanoSpector, verifying “clean” becomes a science—not a guess.