The Importance of Contact Angle Measurements and Wettability in Industrial Manufacturing, Aerospace, Aviation, and Automotive

In the highly competitive fields of industrial manufacturing, aerospace, aviation, and automotive, ensuring optimal surface properties is crucial for product performance and reliability. One of the key factors in achieving this is understanding and controlling wettability through contact angle measurements. Let's explores the significance of these concepts and their applications in addressing industry-specific challenges.

What is Contact Angle Measurement?

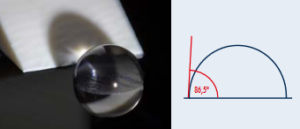

Contact angle measurement is a technique used to determine the wettability of a surface by a liquid. The contact angle is formed at the interface where a liquid droplet meets a solid surface. It provides valuable insights into the interaction between the liquid and the solid, which can impact processes such as coating, painting, adhesion, and cleaning.

- Low Contact Angle (< 90°): Indicates good wettability, meaning the liquid spreads out on the surface. This is desirable for applications requiring strong adhesion, such as coatings and paints.

- High Contact Angle (> 90°): Indicates poor wettability, meaning the liquid forms a bead on the surface. This is useful for creating water-repellent surfaces, such as in aerospace applications.

Operating Principle

Challenges in Industrial Manufacturing

In industrial manufacturing, maintaining surface cleanliness and optimizing adhesion processes are critical. Contaminants or poorly prepared surfaces can lead to product failures and reduced lifespan.

Solution:

- Contact Angle Measurement: By regularly measuring the contact angle, manufacturers can ensure surfaces are clean and properly prepared for subsequent processes. This helps in achieving strong bonds and high-quality finishes.

Applications in Aerospace and Aviation

In aerospace and aviation, surfaces are exposed to extreme conditions, and even minor surface imperfections can lead to catastrophic failures. Wettability plays a vital role in ensuring components perform reliably.

Challenges:

- Surface Coatings: Aircraft surfaces require coatings that can withstand harsh environmental conditions.

- Adhesion and Bonding: Critical components need strong adhesive bonds that can endure high stresses.

Solution:

- Contact Angle Measurement: Ensures surface coatings adhere properly and provide the necessary protection. It also helps in verifying the quality of bonding processes, preventing potential failures.

Enhancing Automotive Manufacturing

The automotive industry relies heavily on surface treatments for durability and aesthetic appeal. From paint adhesion to lubrication, wettability is a key factor.

Challenges:

- Paint and Coating Quality: Ensuring uniform paint application and coating adherence.

- Sealant Performance: Achieving effective sealing to prevent leaks and corrosion.

Solution:

- Contact Angle Measurement: Helps in monitoring and optimizing the surface preparation processes, ensuring high-quality paint finishes and effective sealant application.

Contact Angle Measurement Tool

The SurfaSpector is an easy to use, handheld device that measures the wettability of metal, glass and plastic surfaces. These tests enable users to determine product surface conditions that ensure proper product quality of components prior to assembly or shipping. By conducting these checks, confidence in paint adhesion, weld quality and anti-corrosion conditions can be ensured.

Conclusion

Understanding and controlling wettability through contact angle measurements is essential for addressing the challenges faced in industrial manufacturing, aerospace, aviation, and automotive sectors. By leveraging these measurements, industries can enhance product quality, ensure reliability, and achieve superior performance. Investing in advanced measurement systems and regular surface analysis can lead to significant improvements in manufacturing processes and end products.

If you're looking to optimize your surface treatments and improve product performance, consider integrating contact angle measurements into your quality control processes. Stay ahead in your industry by ensuring your surfaces are always in top condition.