For certain processes, maintaining clean metal parts before advancing to the next manufacturing stage is crucial. However, how can you ensure your surfaces are completely free of contaminants? Enter the CleanoSpector by SITA Messtechnik, a contact-free cleanliness inspection instrument designed to enhance quality assurance in industrial cleaning processes.

Versatile Applications Across Industries

The CleanoSpector is widely used in industries such as automotive, medical device manufacturing, and aerospace, where cleanliness is paramount for product functionality and durability. Its advanced fluorescence measurement technology detects organic contamination, including oil, grease, coolants, release agents, and cleaning fluids. Applications include:

Machined Parts: Inspecting cleanliness after machining to prepare surfaces for subsequent processes like coating or assembly.

Functional Surfaces: Monitoring after selective cleaning processes like laser cleaning, plasma cleaning, and CO2 snow blasting.

Adhesive Bonding: Ensuring aluminum die-cast parts are free of release agents before adhesive bonding.

Welding: Verifying surface cleanliness before laser welding for optimal joint integrity.

Medical & Vacuum Technology: Detecting filmic contamination on components to maintain precision and sterility.

Bonding Pads: Identifying residual agents and encapsulation material on bonding pads before assembly.

Electrical Contacts: Inspecting surfaces post-isolation stripping to ensure proper electrical conductivity.

Protective Coatings: Assessing layer thickness for corrosion protection oils or primers to confirm proper application.

Ease of Use and Accuracy

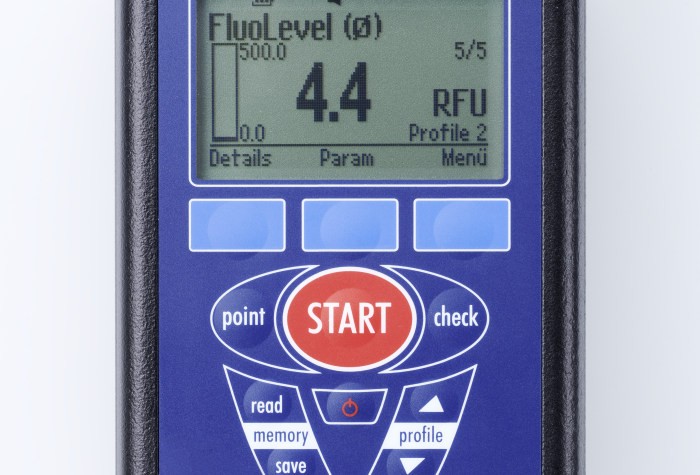

At the push of a button, CleanoSpector provides non-contact, non-destructive surface inspection, offering precise cleanliness evaluations displayed as a percentage. The fluorescence measurement principle relies on UV light emission and detection of reflected fluorescence to determine the contamination's intensity. Spacers are available to facilitate measurements of various part shapes, ensuring optimal focal length and repeatable results.

Benefits for Quality Assurance

- Process Optimization: By identifying parameter deviations early, the CleanoSpector enhances process reliability, reduces waste, and ensures compliance with cleaning system specifications.

- Data Management: With optional software, users can control measurements via PC, graphically display measuring points, analyze saved data, and prepare detailed test reports for traceability.

- Flexible Deployment: Designed for laboratory and shop floor use, this portable device operates reliably under varying conditions, supported by a robust build and long battery life.

The CleanoSpector stands as a cornerstone for ensuring product quality, reducing manufacturing defects, and meeting stringent cleanliness standards across industries. Whether ensuring a clean start for a medical implant or verifying the cleanliness of aerospace components, the CleanoSpector delivers unmatched precision and reliability.