Monitor Surface Tension Process Measurement

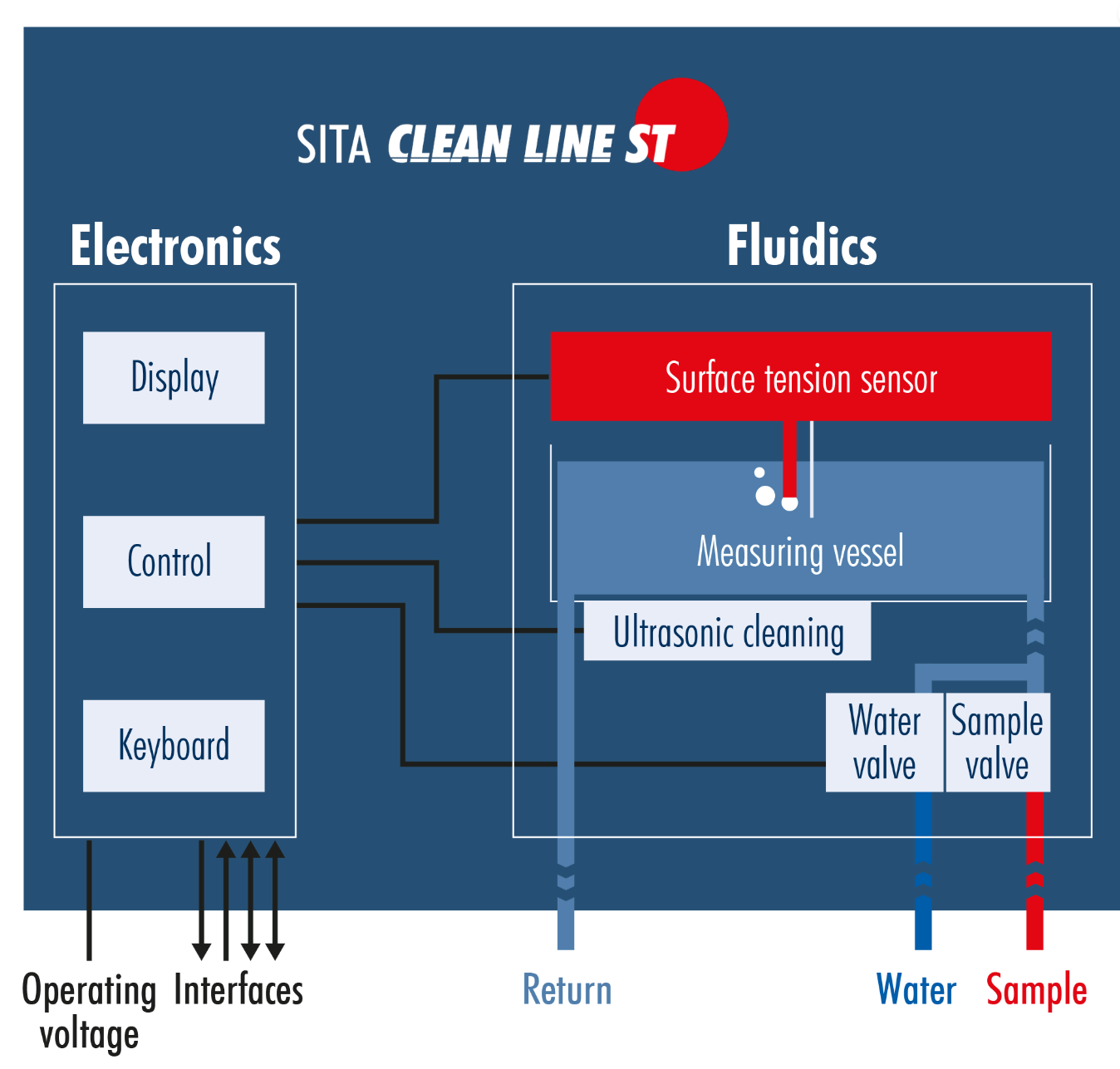

The SITA clean line ST is an advanced process tensiometer designed to measure the surface tension of process solutions with precision and reliability.

The process liquid sample is either lead back into the process again or rejected. No further equipment is necessary except of a tap water supply.

SITA application engineers develop an optimal and customised SITA clean line system solution based on an analysis of your process and plant.

- Fully automated measurement of the surface tension of process liquids

- Monitoring and controlling the surfactant/wetting agent concentration

- Continuous and discontinuous measurement (intervals or request)

- Automatic cleaning, calibration, monitoring

Reliable process tensiometer

The process Tensiometer SITA clean line ST automatically measures the Surface tension of process liquids used in the parts cleaning industry, surface technology, semiconductor and photovoltaic industry as well as the chemical industry.

The process parameter surface tension, and thus the concentration of Surface-active agents like Surfactants, wetting agents and solvents, are measured and documented inline. Connected to the plant control, the SITA clean line ST measuring system carries out an automatic dosing of active agents according to the consumption.

Application

Continuous monitoring and dosage according to the consumption:

- Cleaning agent component surfactant in baths of industrial parts cleaning of companies operating in the field of mechanical engineering, automobile industry, electrical engineering and microelectronics

- IPA-Concentration in texturing baths for silicon-wafers of photovoltaic industry

- Wetting agent concentration of developer solutions for lithography processes of the semiconductor industry

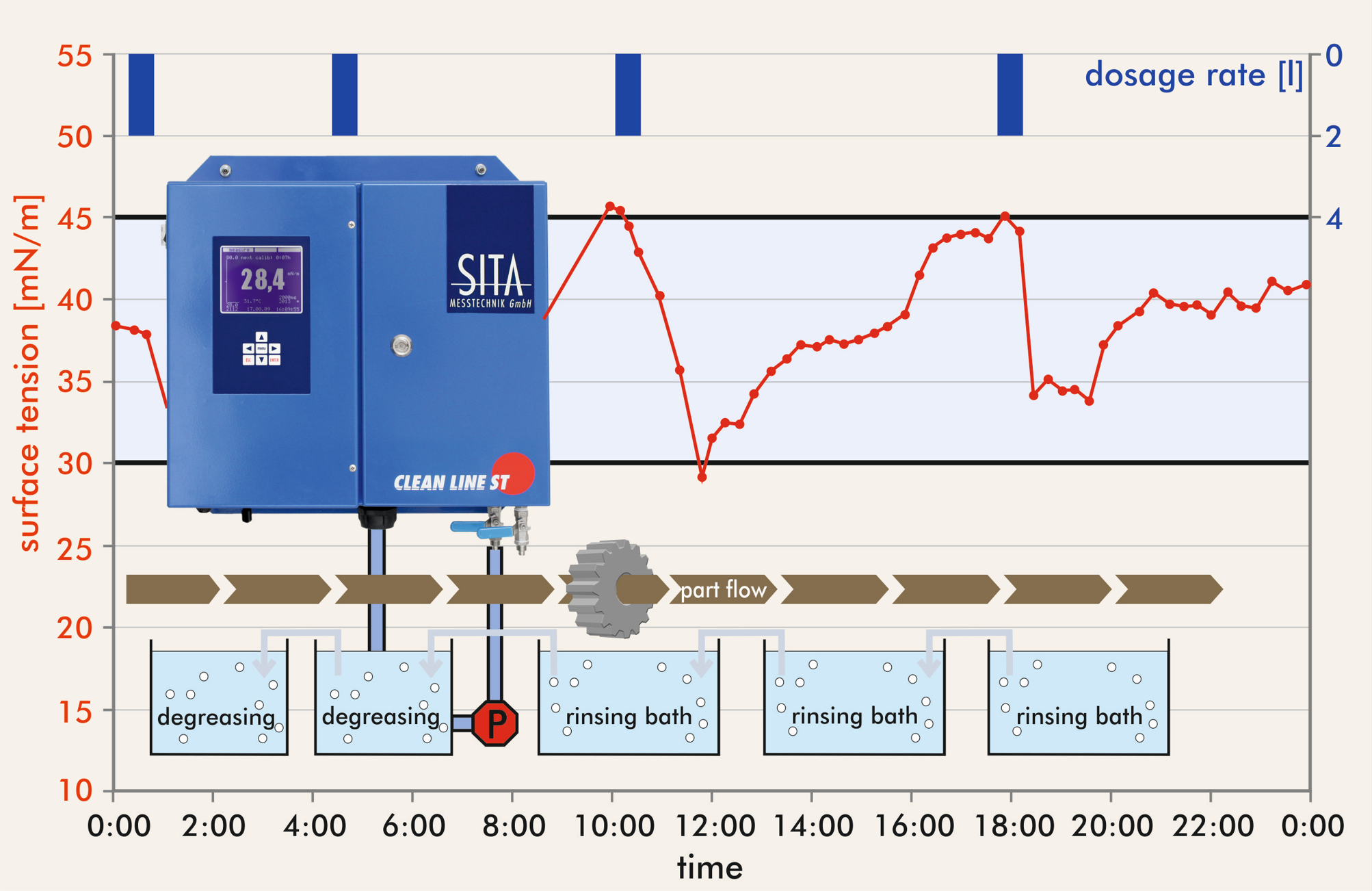

Practical example: automatic cleaning agent dosing before coating automotive pistons

High Cleanliness standards of automotive piston surfaces before coating with an anti-friction-layer require a management of the cleaning agent concentration within pre-determined limit values.

The system solution SITA clean line ST continually monitors the cleaning agent components and ensures their dosage according to the consumption. Thus, a depletion or an overdose of cleaning agent can be avoided guaranteeing an optimal cleaning quality. The process reliability can be sustainably increased as well as the efficiency through to a reduction of cleaning agent.

Measuring Principle

The SITA clean line ST process measuring device also uses the bubble pressure method to measure the dynamic surface tension in liquids.

To this end, a robust system developed for process use Capillary an air flow was introduced into the sample liquid and the pressure curve for bubble formation was measured, as the picture shows.