Setting the Standard

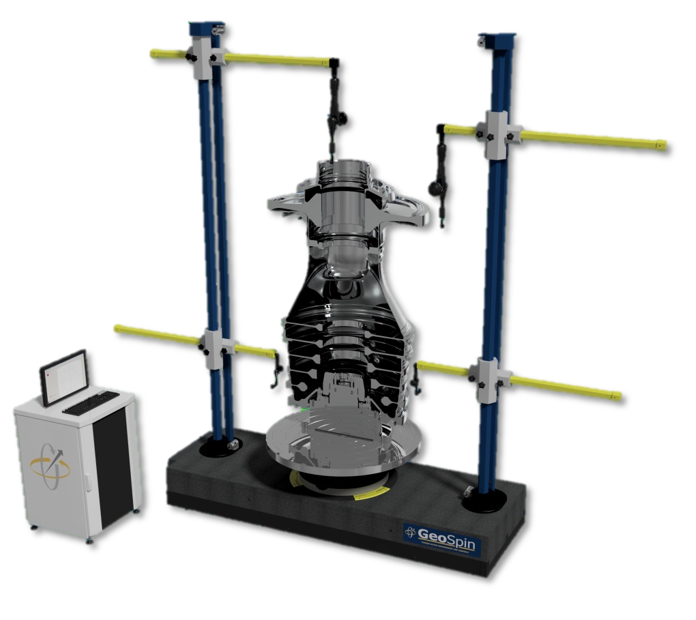

Using the same technology as its big brother, iMAP, GeoSpin provides ultra high precision, high speed, shop floor circular geometry inspection for small and medium parts of up to 3,500lbs.

Incorporating AccuScan technology, GeoSpin quickly and accurately measures circular geometry features such as Roundness, Eccentricity, Diametral Runout, Planar Runout, Circular Flatness and Parallelism.

Key Benefits

- Quick and easy to use

- High precision, repeatable results on the shop floor

- Wide range of configuration options to suit your application

- Easily create and share measurement plans and dimensional reports

- Incorporate with Intellistack predictive stacking software to allow optimized assembly of turbine stages to improve balance and reduce operating vibration

Typical Applications

GeoSpin is designed to provide quick and accurate shop floor inspection of small and medium sized turbines, turbine components, drive train components and similar parts.

Typically, this is within the aerospace sector within OEM and Tier 1 manufacturers, along with manufacturers within the energy sector.

GeoSpin also offers significant benefits to the MRO sector, too, increasing measurement quality and decreasing maintenance time.