High Speed Contact Angle Wettability Measurement

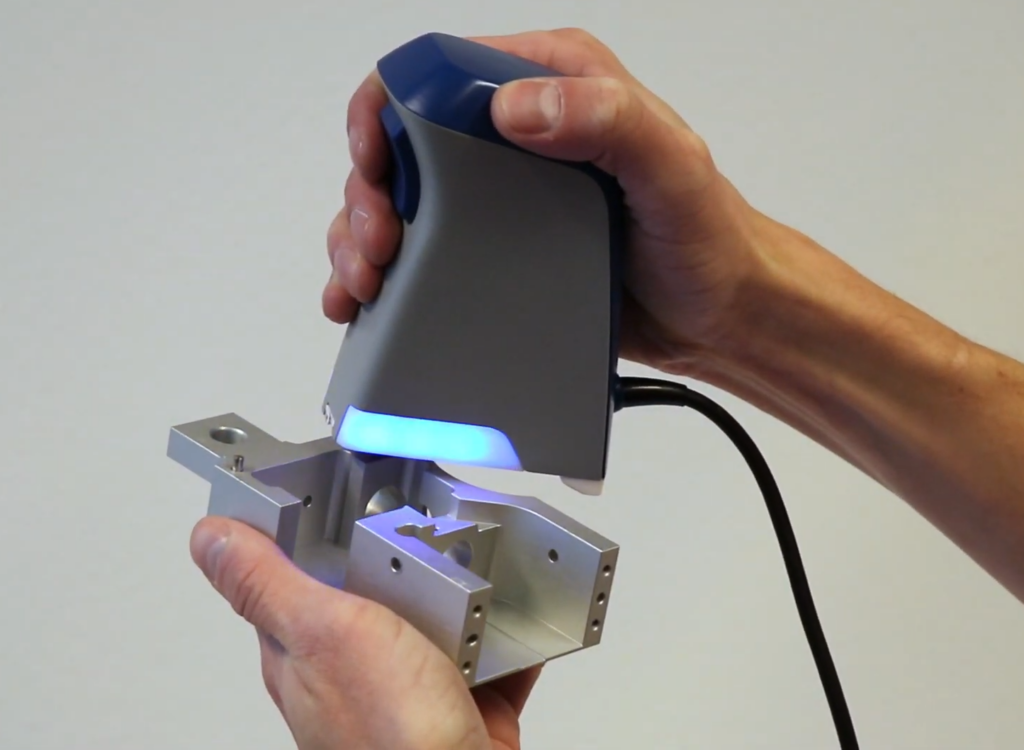

SurfaSpector is an easy to use, handheld device that measures the wettability of metal, glass and plastic surfaces. These tests enable users to determine product surface conditions that ensure proper product quality of components prior to assembly or shipping. By conducting these checks, confidence in paint adhesion, weld quality and anti-corrosion conditions can be ensured.

High Speed, Traceable and Quantifiable Measurement

Unlike other more simplistic approaches to wettability testing, SurfaSpector can be used quickly, with a typical test taking only seconds. The results for each measurement can be permanently stored, ensuring a traceable record for Quality Assurance purposes. Because SurfaSpector gives a measured value, the results are no longer subjective: Every measurement is subject to the same measurement criteria ensuring consistency across operators.

Superb Ergonomics

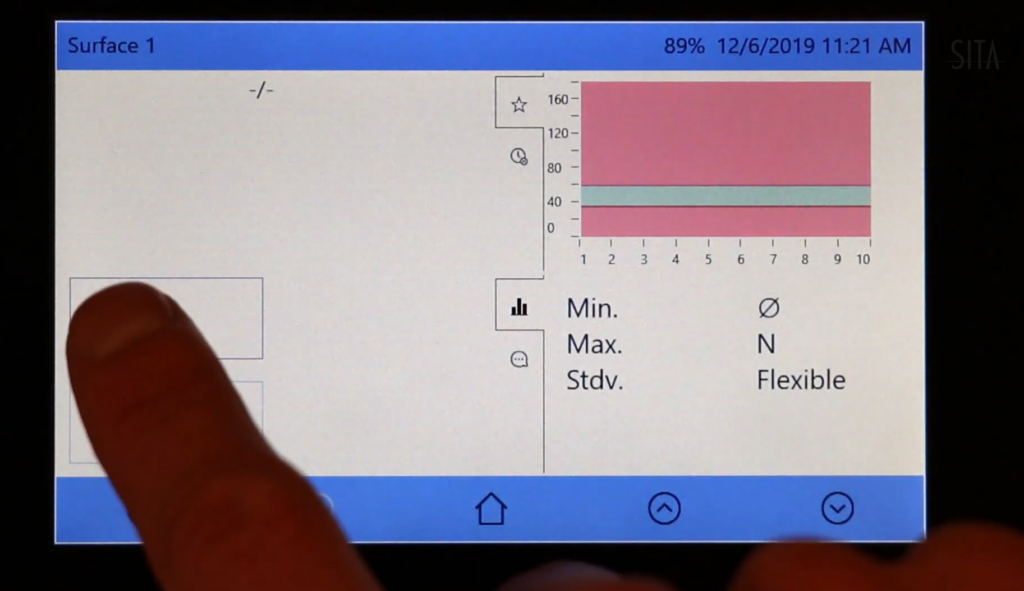

With an easy to use touchscreen and rechargeable LiIon battery that lasts for 6 hours, the SurfaSpector can be easily used in multiple locations for an entire shift. Measured results can be transferred to a PC for analsyis via the supplied USB-C cable, and the entire unit can be operated in a standalone form factor in day to day use.

Customizable Reporting and Planning

SurfaSpector has a stoarge capacity of 10Gb, meaning tens of thousands of measurements can easily be stored. It's also easy to setup measurement routines, specification limits and programs, enabling specifc parts to be measured, recorded, audited and stored for future use.

Ease of use means faster implementation

SurfaSpector is incredibly easy to use. An operator can be shown how to collect measurements in minutes, whilst full training, including programming, maintenance and advanced operation is extremely quick, too. That means implementation takes minimal time, allowing rapid deployment of equipment to achieve real world results.

Typical Applications

SurfaSpector is an ideal tool for helping improve product quality in a wide range of siutations. Popular applications include:

Operating Principle

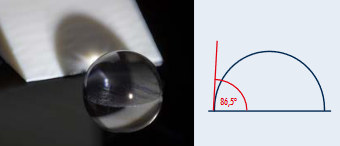

A precisely dosed drop of water is automatically applied to the surface of the measurement area. This drop is then illuminated from the side, and a shadow is projected onto the device measurement surface. A high resolution camera then records this shadow from above a determines the angle through triangulation.

If the contact angle is lower (and so, the drop is wider and lower), the higher the wettability.

Specifications

Contact Angle

Range: 5-175 deg

Resolution: 0.1 deg

Liquid: pure water, refillable, capacity 5ml (5,000 measurements)

Method

Drop volume: 1μl

Min. sample surface: 5x5mm

Operation

Control Unit: 5" TFT display, 800x480 pixel, capacative touchscreen

Unit Dimensions: Measurement start button, optical LED feedback

Power

LiIon Battery: 12,800mAh, measurement time 6 hours

Power Input: 12v, 2.5A (max. 17v, 3A)

Interface/Memory

USB: Data transfer, USB-C power source

Memory: 10Gb

Dimensions and Weight

Control unit: 80x210x130mm, 1,100g (3.1x8.3x5.1 inch, 2.4lb)

Sensor: 117x50x82mm, 330g (4.6x2.0x3.2 inch, 0.7lb)

Available Accessories

Calibration standard, stand

Want to know more?

We're always happy to discuss your requirements, potential applications and talk through concepts to help improve productivity and quality