Quickest & Easiest Way to Measure Surface Cleanliness

The contact-free measurement system that allows multiple surfaces to be measured in the palm of your hand has been updated to help you inspect faster, improve traceability, and reduce damaging. Designed with flexibility in mind, the CleanoSpector works to detect oils, greases, parting agents, and cooling lubricants on parts and assemblies made of metal, ceramics and/or glass.

Multiple Ways to Measure

Spot Check

Detect any surface contamination of your part's surface directing the beam of the CleanoSpector onto a specific point. The stronger the fluorescence, the greater the level of contamination at that spot. This allows you to quickly determine cleanliness at specific, critical areas.

FluoStep (Automatic Trigger)

Individually measure 10 sample points in sequence, one after each second. Increase speed options of measurement sampling time to less than half a second.

FluoScan (Automatic Scanning)

Continuously scan circle or spiral paths automatically like discs, wheels or rings and cylinders up to 250 sample points. With 10 readings per second, get live display of readings.

High Speed

CleanoSpector is quick to implement and takes measurements in seconds. This makes integrating it into your quality process seamless, ensuring you see results as soon as you start using it.

FluoScan (Trigger Mode)

Shop Floor Suitability

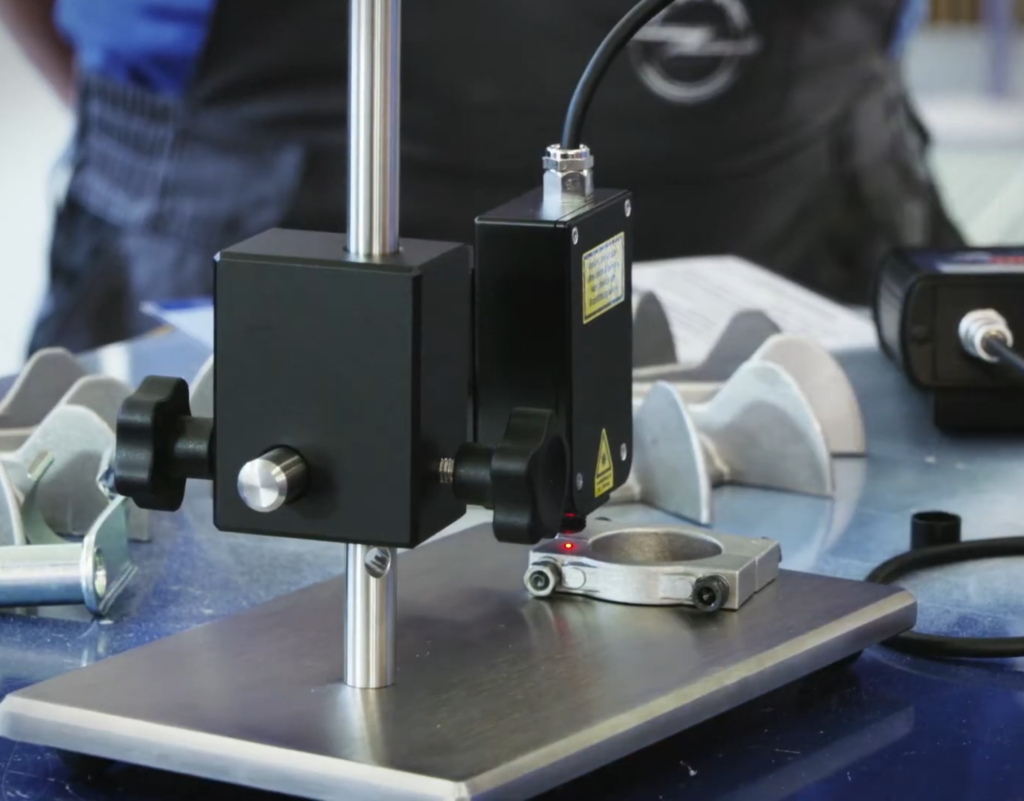

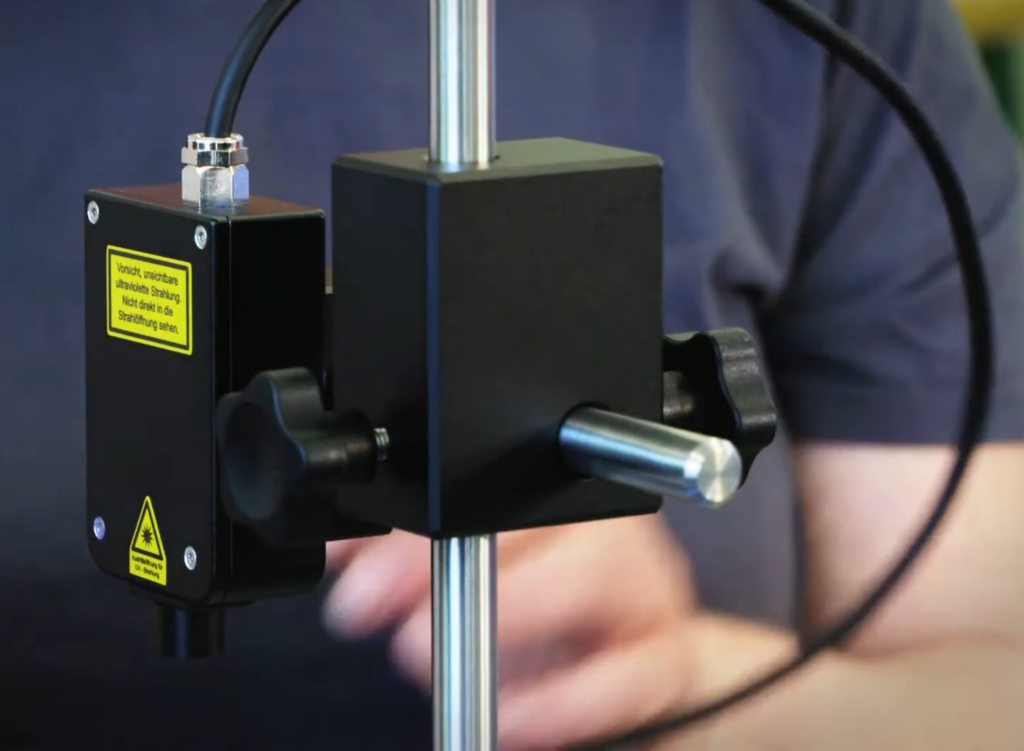

CleanoSpector uses optical sensing technology to collect measurements. That means that it is able to operate with no contact to the part it is measuring. By using the supplied adjustable stand, parts can easily and repeatably be loaded under the sensor to create an easy inspection process that any operator can conduct.

In cases where parts are larger, the sensor can be removed from the magnetic mount easily, and used with a standoff to enable measurement of virtually any part design.

Reporting & Data Handling

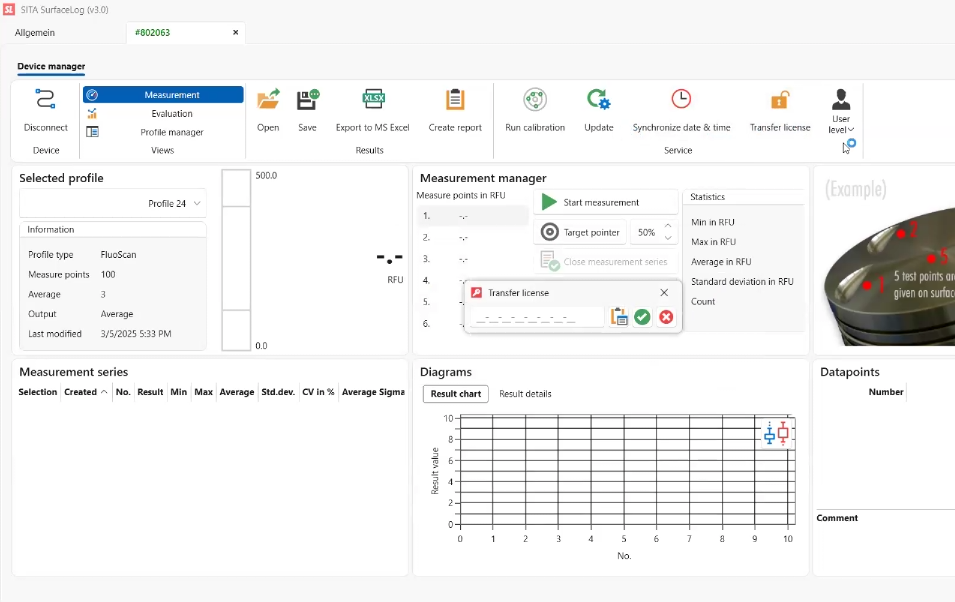

New Comprehensive Measurement Data Software with an easy to read LCD display shows results as they are collected, whilst they are also stored onboard, enabling download of results via USB at a later stage to the optional SITA ProcessLog software, allowing full traceability of data.

Gone are the days of guessing cleaning bath conditions, or using trial and error. CleanoSpector provides a reliable method of measurement that is consistent across operators.

SurfaceLog can operate as a stand-alone system

Typical Applications

CleanoSpector's flexibility means that it is suited to a wide range of applications. If you need to check a part for surface contamination, it is an ideal system for the task. Some of the most common applications CleanoSpector is used for include:

- Ensuring parts are clean prior to painting to prevent premature paint loss

- Inspecting parts after cleaning processes have been conducted

- Checking cleanliness of surfaces prior to welding, reducing weld splatter

- Ensuring sufficient protective coatings have been applied to machined components

- Checking surfaces for cleanliness that could impact electrical conductivity

- Ensuring parts used in vacuum, pneumatic, hydraulic or medical applications are sufficiently clean

- Checking that protective and adhesive coatings have sufficient thickness on a part

Operating Principle

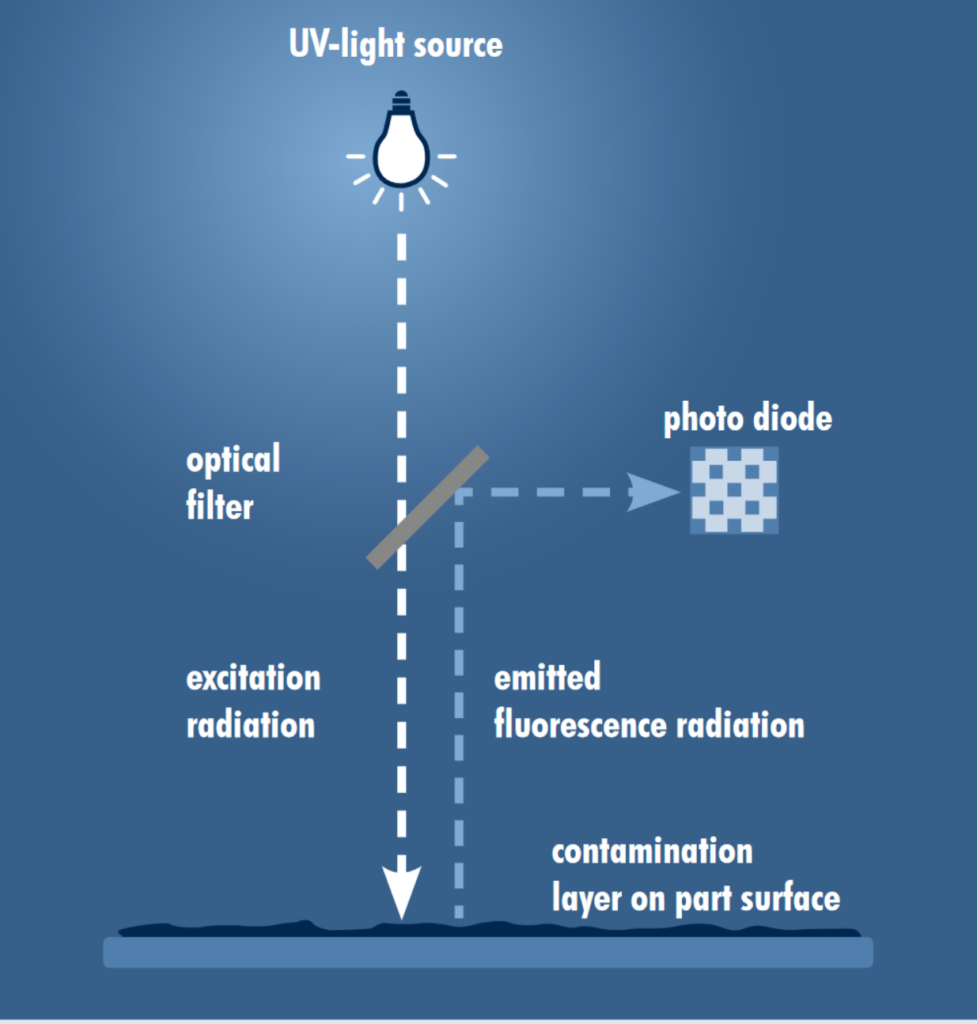

CleanoSpector uses optical sensing technology to determine part cleanliness. Filmic contaminants fluoresce when exposed to UV light.

The device takes advantage of this quality by exposing the surface of a part to a controlled level of UV light. This is then reflected back to a sensor close to the light source. By measuring the level of UV light returned, the contamination level is reported as an RFU value (Relative Fluorescence Unit). The higher the value that is returned, the greater the contamination level.

Specifications

| Fluorescence intensity | |

| Measuring range | 0-2,000 RFU (Relative Fluorescence Unit) |

| Max. measuring deviation | 0.5 % of measuring range |

| Resolution | 0.1 RFU |

| Sensor optics | |

| Excitation | 365 nm, max. 150 mW |

| Detection* | 460 nm |

| Measuring point* | D=1 mm |

| Measuring distance* | 4.7 mm (0.2") |

| * standard values | |

| Cleanliness | |

| Measuring range | 0-100 % |

| Resolution | 0.1 % |

| Layer thickness | |

| Measuring range | user-defined |

| Power supply | |

| Li-Ion-battery | 3.6 V/1,950 mAh, min. 8 h operating hours |

| Power adapter / USB | 100-240 V / 5 V |

| Power consumption | 2.5 W max. |

| Interface, memory, dimension, weight | |

| USB-interface | Data transfer |

| Display | LCD, illuminated |

| Measuring profiles | 254 |

| Memory | 8,000 measuring values per profile |

| Dimensions (HxWxD) | Hand-held device: 129x82x48 mm (5x3.2x1.9") Sensor head: 95x50x30 mm (3.7x2x1.2") |

| Weight (device) | 530g (18.5oz) |