Real-World Example of the affects of Bath Contamination

In the aerospace and energy industries, turbine blades play a critical role in the performance of jet engines, power plants, and more. These high-performance components are designed to withstand extreme conditions and deliver consistent power. However, the presence of contaminants on turbine blades due to improperly cleaned manufacturing baths can lead to significant issues, affecting both consumers and manufacturers. Let’s explore why bath contamination occurs, how it impacts consumers, and how advanced monitoring tools like the SITA ConSpector can help mitigate this risk.

The Problem: Contaminated Turbine Blades in Manufacturing

During the manufacturing process, turbine blades go through rigorous cleaning stages in specialized baths to remove oils, greases, particles, and other residues from previous steps. However, over time, these baths themselves can become contaminated with oils, dirt, and particles that accumulate from each batch of parts cleaned. If not monitored and maintained, the cleaning baths lose effectiveness, and residues can redeposit on turbine blades instead of being removed.

For high-stakes applications like aerospace engines, contaminated blades pose serious risks. Even tiny particles or residues left on turbine blades can disrupt their efficiency, reduce lifespan, and even lead to catastrophic failures. For instance, particle buildup on blades can create drag, heat spots, or even lead to fractures under stress, compromising the entire turbine’s function.

Impact on Consumers

Consumers may not immediately connect turbine blade cleanliness to the products and services they rely on daily, but the effects are far-reaching:

- Air Travel Safety and Reliability: In the aerospace industry, turbine blade contamination can lead to engine malfunctions, affecting flight safety and reliability. Engine issues due to contaminated parts can cause delays, costly repairs, or even emergency landings, impacting travelers worldwide.

- Increased Costs for Energy Production: In power plants, contaminated turbine blades can reduce efficiency and increase maintenance needs, leading to higher operational costs. These costs can ultimately be passed on to consumers in the form of higher energy bills, affecting households and businesses.

- Reduced Product Longevity: Turbine blades are expected to last for years, if not decades. However, contamination issues can cut their lifespan short, requiring earlier replacement. Consumers, as a result, may face rising costs as manufacturers and industries account for more frequent repairs and replacements.

Solution: How the SITA ConSpector Mitigates Bath Contamination Risks

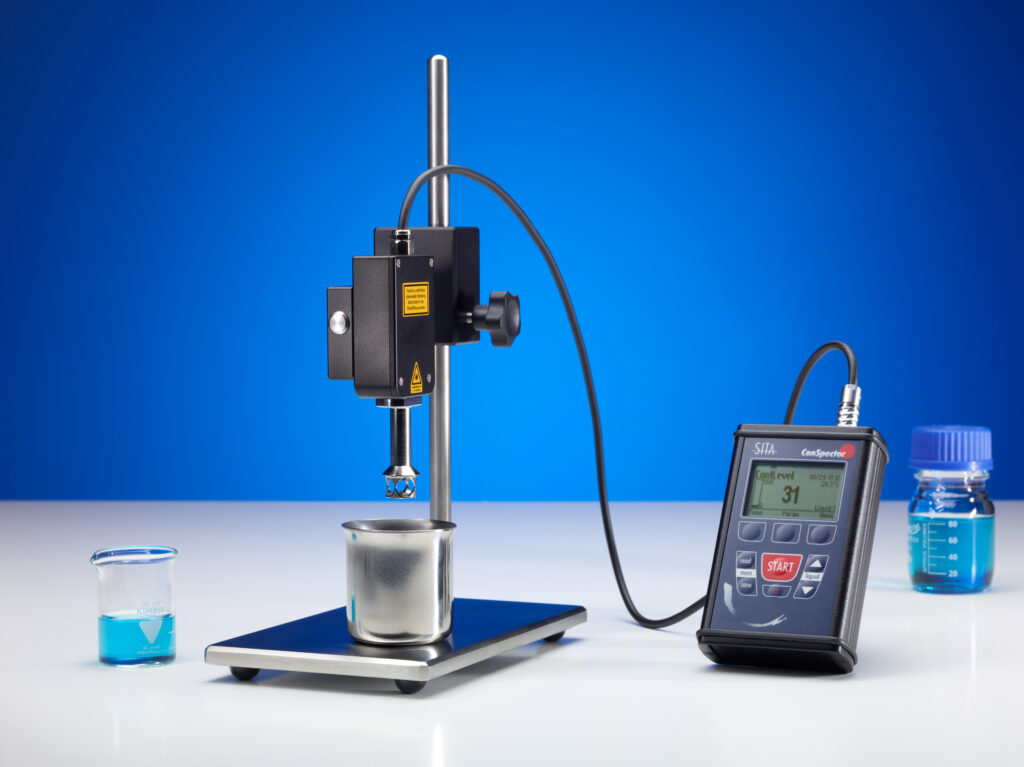

To ensure that turbine blades and other critical components are thoroughly cleaned, advanced bath contamination monitoring is essential. This is where the SITA ConSpector comes into play. This device provides real-time, objective data on bath contamination levels, helping manufacturers maintain optimal cleanliness. Here’s how the ConSpector addresses contamination issues and protects product quality:

- Real-Time Monitoring of Contaminants: The ConSpector uses a UV-light source to detect contaminants like oils, greases, and cooling lubricants in the bath. By measuring fluorescence from these substances, it provides an accurate reading of contamination levels. This real-time feedback allows manufacturers to assess when a cleaning bath has reached a contamination threshold and needs to be replaced or treated, preventing contaminants from building up on turbine blades.

- Extending Bath Lifespan and Reducing Waste: With objective data, manufacturers can avoid replacing baths too early (wasting resources) or too late (risking contamination). By optimizing bath lifespans, companies can reduce waste, lower maintenance costs, and maintain consistent cleaning effectiveness, ultimately passing cost savings on to consumers.

- Documented Quality Assurance: The ConSpector’s optional SITA-ProcessLog software enables quality control teams to document and track contamination data over time. This not only supports quality assurance efforts but also provides a record that manufacturers can use to meet regulatory requirements and provide transparency to customers and stakeholders.

- Improved Safety and Reliability: By ensuring that turbine blades are cleaned in properly maintained baths, manufacturers significantly reduce the risk of contamination-related failures. For consumers, this means safer, more reliable flights, stable energy production, and longer-lasting products.

Conclusion: A Cleaner Path to Quality and Reliability

For industries that depend on turbine blades and other high-performance components, managing bath contamination is more than just a maintenance step; it’s a crucial part of ensuring product quality, consumer safety, and cost efficiency. With tools like the SITA ConSpector, manufacturers can gain control over contamination, maintain high standards of cleanliness, and ultimately deliver better, safer products to consumers.

The next time you board a plane or enjoy the benefits of consistent energy, you can rest assured knowing that technologies like the ConSpector are helping make these experiences safer and more reliable. Proper contamination control isn’t just about manufacturing — it’s about safeguarding the quality and reliability that consumers expect every day.