Large and heavy parts are by their nature cumbersome to move and inspect. That’s a given. But how do you overcome this without sacrificing accuracy and repeatability? Fortunately, there’s a solution to this problem. That solution is GeoOrdinate.

What is GeoOrdinate?

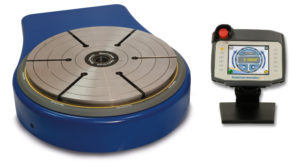

GeoOrdinate is a rotary system that can position with an accuracy of as little as 0.5 arcseconds (0.0001 degrees). Even more impressively than this, it can do it on the shop floor…. Not just in the controlled conditions of a metrology laboratory.

This is a boon for anyone who manufactures or inspects large components that are also precision built to tight tolerances. Driven by a highly precise motor drive system, the system can be specified to accommodate loads as heavy as 5 tons (10,000 lbs) and with a table top diameter of up to 1,000mm (39.5”) – and tooling can allow parts even larger than this to be mounted. A range of smaller options is available, too. With this kind of flexibility, it’s possible to there are suitable models for a multitude of uses.

Flexible features allow customization to your task

As you might expect, GeoOrdinate has a range of features that lend itself perfectly to this type of inspection task.

There’s a range of control options to allow optimal positioning of parts. Firstly, there’s ArcMotion. This is a user-friendly control unit that allows repeatable positioning via an easy to use touchscreen graphical display.

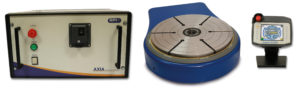

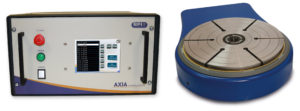

There are also situations where you might want to use more advanced programing options. For example, you might want to move to set positions repeatedly. This is useful for inspecting specific features in set places, or repeated patterned features such as gear teeth.

Those kinds of scenarios are covered, too, using the Axia advanced controller unit. Axia also offers another benefit: Its simple programming interface and outputting means it is easy to integrate with other systems for automation and control – such as other measurement and inspection systems. Naturally, you can also use both Axia and ArcMotion if you intend to use GeoOrdinate for more than one application.

Ease of use comes as standard

When parts are large and space is limited, working surfaces can be at a premium. Another feature of GeoOrdinate can help here. The system can be specified with an Air Flotation base. This simple, yet highly effective, solution enables you to glide GeoOrdinate into another position in cases where you need to use the surface area for another activity. It also allows for easier and unloading of parts in cases where access is restricted.

To further aid part loading and positioning, a range of tooling options can be supplied to simplify the process.

Robust design for heavy duty use

It goes without saying that along with ease of use and world leading accuracy, robustness is a strong focus here. This is a system that is designed for high duty cycles. Use in a shop floor environment is a central focus of GeoOrdinate. All the while not losing that world leading accuracy and repeatability.

If you need to position or index a large, heavy or cumbersome part with the best accuracy and repeatability you can possibly get, there’s one solution ideally suited to the task. That solution is GeoOrdinate.

You can get more data about GeoOrdinate here. If you’d like to talk more about your application, contact us today. We’re always happy to hear from you.

Contact Us