Despite the wealth of new technologies on the market, the trusty Coordinate Measurement Machine (CMM) remains a mainstay of inspection for most manufacturers. Why is this? For one part, it is a known quantity, but there’s more to it than that. It’s also flexible, accurate, and reliable. Those are all important qualities to possess when dealing in something as quantifiably precise as metrology.

The popularity of CMMs mean that many of us come to rely on them for day-to-day quality control. They are often used for routine inspections, and as production ramps up, or requirements change, this can introduce strain into an otherwise (hopefully) smoothly running process.

That can introduce a dreaded bottleneck into inspection when parts reach the CMM room, something many are familiar with. This can be a big problem. With not enough inspection capacity, compromises often must be made. Do you reduce the amount of parts inspected? Do you reduce the number of inspection points? Do you do something more radical? Maybe add more CMMs? How about outsourcing some inspection to a third party? Maybe there’s just an ever-increasing queue of parts waiting to be inspected. That’s never a good situation.

Whichever approach is taken, it can be costly. Inappropriate inspection strategies can lead to QA failures later in production (or worse, after parts are delivered). Reduced throughput can affect production rates. Whatever option is chosen, it can be extremely disruptive.

Of course, one approach (perhaps in many cases, an ideal approach if practicality weren’t an issue) would be to keep adding CMMs until there was enough capacity to cover all requirements. That would be extremely expensive, though. And realistically, having enough space to add additional bulky machines (especially if they are going to be used in temperature-controlled environments) can often be a challenge.

That being the case, increasing the capacity of existing machines seems the ideal way to overcome this impasse. The Quadrant range is designed to do exactly that.

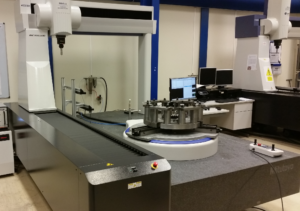

The Quadrant range of rotary tables act as an additional axis on a CMM, creating a more flexible approach to inspection on the machine. Before moving the probe to the part to take a measurement, the part can be rotated into a position much closer to the probe tip. This reduces probe travel time, thereby increasing measurement speed significantly.

Typical benchmarks have shown an average improvement in inspection speed (and subsequently increased machine capacity) of 40%. That’s a significant reduction in inspection bottlenecks.

The Quadrant range is the world’s leading CMM rotary axis range, and with good reason. Not only does it boast superb robustness and durability, it also is extremely accurate and repeatable. A typical unit has an angular repeatability of just 0.5 arcseconds (0.0001 degrees). This extremely high level of performance means that the unit has virtually no impact on a CMM’s uncertainty budget.

It really does create the dream scenario… Add extra measurement capacity to an area renowned for bottlenecks without the cost or space considerations that adding extra CMMs brings.

The Quadrant range works with any CMM, so if you are looking for a way to alleviate those pesky CMM bottlenecks, it’s the most logical choice. If you’d like to know more about the range or discuss the details of how adding a rotary stage to a CMM is beneficial, don’t hesitate to contact us!