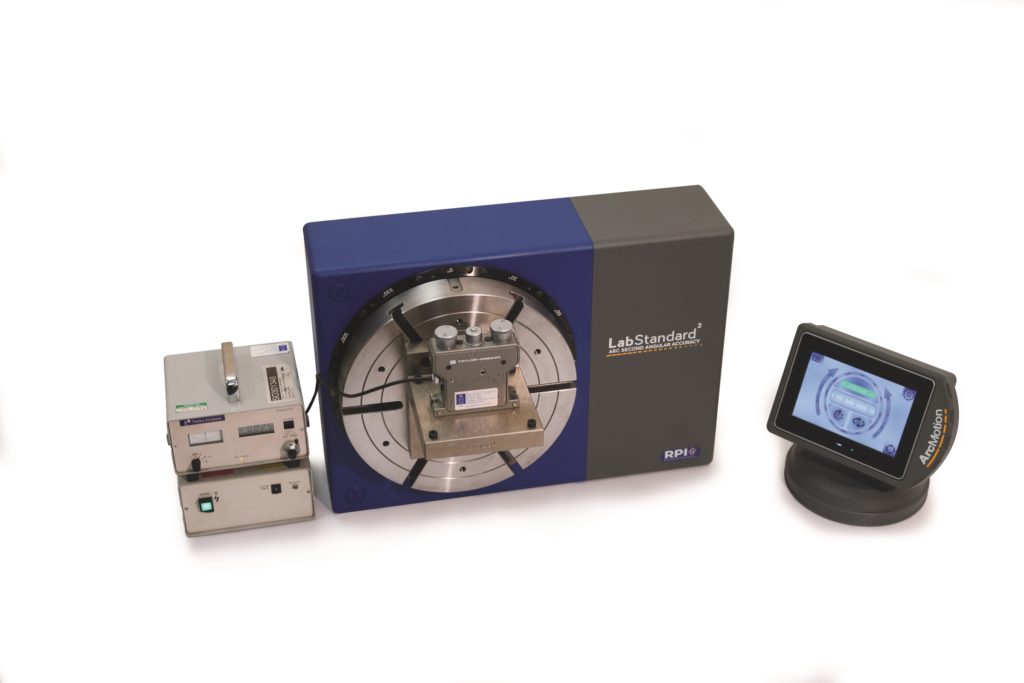

You’d think that with a product name like LabStandard would mean it was designed for use in a clean, controlled metrology lab. Not so! It is capable of a whole host of applications from the lab to the shop floor beyond what its name belies.

The secret is in the underlying principles of all our rotary products

In keeping with the rest of the range, LabStandard offers world leading metrology performance and shop floor hardness in one package. This allows it to fit comfortably into all sorts of environments.

Let’s have a look at some of the applications that allows the LabStandard to perform.

You’d expect LabStandard to live in the lab…

It should come as no surprise to discover a LabStandard in a lab. The amount of applications in the lab alone are vast. LabStandard can be specified with a positional accuracy of +/- 0.5 arc seconds (0.00014 degrees) which sees to that.

That kind of performance means that LabStandard can conduct an array of calibration tasks quickly and easily. A wide range of angular calibrations become possible. Items such as gyroscopes, positional sensors and so on can be calibrated and checked easily.

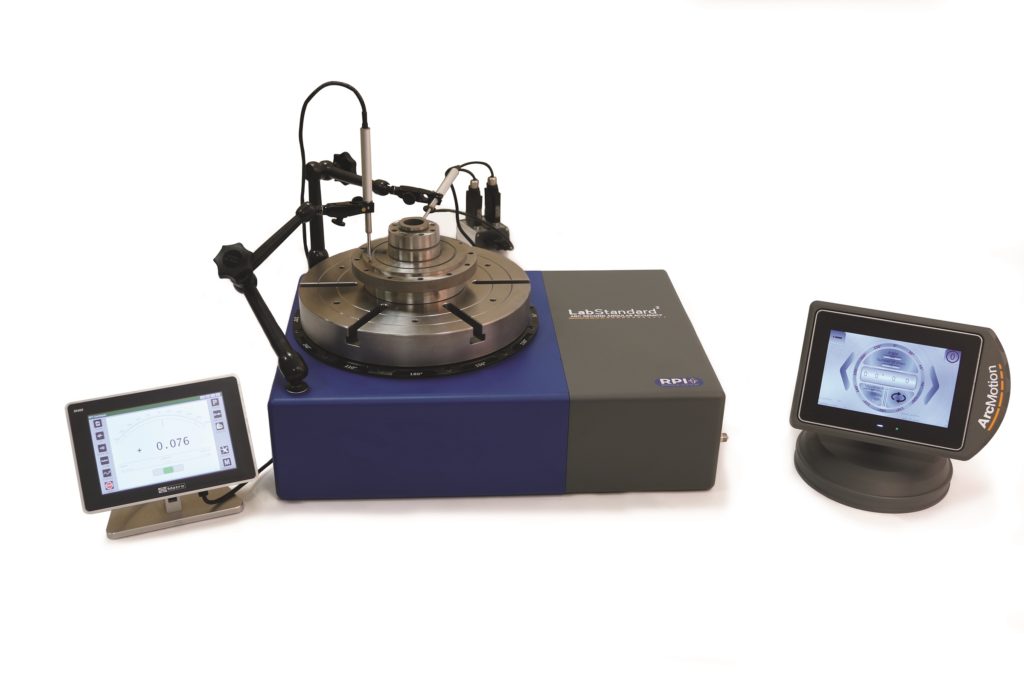

LabStandard’s second home

The LabStandard finds a new selection of applications on the shop floor. This is helped in no small part by another of its party pieces: It can be mounted vertically as well as horizontally.

That means on the shop floor LabStandard can help with a wide variety of tasks such as precision grinding and boring as well as precision positioning.

Precision rotary metrology for all environments

So, there you have it: Proof positive that there’s more to LabStandard than the name might suggest. It’s small footprint, robust design and excellent rotary performance make it the product of choice for a wide variety of both calibration and machining tasks. Such versatility, eh?

You can get extra data on LabStandard systems here.