Ensuring Cleanliness and Quality

In today's precision-driven industries, maintaining stringent cleanliness standards is crucial for product quality and reliability. Surface particle counters have emerged as indispensable tools across various sectors, including aerospace, automotive, electronics, and medical devices. Here’s why Benefits of a Surface Particle Counter in your quality control processes can make a significant difference.

Enhanced Cleanliness Control

Surface particle counters offer precise measurement of particle contamination on surfaces, ensuring that cleanliness standards are consistently met. The ability to obtain real-time results allows for immediate corrective actions, maintaining optimal cleanliness conditions throughout production.

Application Use

Pharmaceutical Industry: Monitoring surfaces during the manufacturing process to ensure compliance with regulatory standards.

Research and Development Laboratories: Ensuring that surfaces in laboratories are free from particles that could interfere with experiments. As well as monitoring and controlling particle levels in cleanrooms where sensitive research and development activities take place.

Quality Assurance

Regular monitoring with a surface particle counter ensures surfaces consistently meet cleanliness specifications, reducing the risk of product defects caused by contamination. These instruments help meet industry-specific cleanliness standards and regulations, safeguarding the quality of your products and ensuring compliance.

Regular monitoring can identify trends in contamination, allowing for preventive maintenance before contamination levels reach critical thresholds.

Application uses when verifying cleanliness

Assembly lines in Aerospace: Verifying the cleanliness of surfaces in cleanrooms where sensitive components are assembled, such as avionics and instrumentation.

Powertrain Components in the Automotive Industry: Ensuring that transmission parts are free from contaminants to prevent wear and improve longevity.

Process Optimization

Surface particle counters are invaluable for evaluating the effectiveness of cleaning processes. By providing detailed insights into particle levels, these instruments help optimize cleaning protocols, leading to improved results and cost savings by identifying areas of over-cleaning.

By maintaining optimal cleanliness levels, the likelihood of defects caused by contamination is minimized, leading to lower rejection rates and cost savings in rework and scrap.

Improved Product Performance and Longevity

Minimizing surface contamination directly correlates with higher quality products and reduced defect rates. Clean surfaces ensure reliable performance, especially in industries like aerospace and electronics, where precision and reliability are paramount.

Application Uses

Automotive:

- Monitoring the cleanliness of fuel injectors and related components to ensure optimal performance and fuel efficiency.

- Detecting and preventing contamination in critical engine parts to avoid wear and tear.

- Ensuring surfaces are free from particles that could affect paint adhesion and finish quality.

Environmental Control

Surface particle counters play a critical role in maintaining cleanroom standards, ensuring environments are free from harmful particulates. By reducing the risk of cross-contamination, these instruments contribute to safer, more controlled production processes.

Application Uses

Cleanroom Environment Monitoring in Pharmaceutical, Medical Device Manufacturing, Electronics and Semiconductor Industry

- Ensuring that production areas meet required cleanliness levels to prevent contamination of drugs and vaccines.

- Monitor and maintain the cleanliness of surfaces in sterile production areas.

- Maintaining ultra-clean environments for the production of microchips and electronic components.

- Ensuring that surfaces of wafers, circuit boards, and other components are particle-free to prevent malfunctions.

- Ensuring that precision-manufactured parts and components are free from contaminants that could affect performance.

- Maintaining the cleanliness of lenses, mirrors, and other optical components to ensure high performance.

Documentation and Reporting

Comprehensive data logging capabilities of surface particle counters provide valuable documentation of cleanliness levels over time. This is essential for audits, quality control records, and traceability, helping quickly pinpoint the source of any contamination issues.

Detailed reports help trace the source of contamination when issues arise, allowing for swift corrective actions. And maintaining records of cleanliness for each production batch enhances traceability, which is crucial for quality control and recall management. Long-term data collection allows for the analysis of cleanliness trends, helping to identify areas for improvement and optimize overall process performance. And reports can be used to benchmark cleanliness performance against industry standards or historical data, driving continuous improvement initiatives.

Versatility

Surface particle counters are versatile tools suitable for various industries including aerospace, automotive, pharmaceuticals, food and beverage, and electronics. Their portability allows for use in different locations within a facility or even in the field, making them adaptable to diverse cleanliness monitoring needs. These instruments can be used in a wide range of environments, from cleanrooms and laboratories to manufacturing floors and maintenance areas.

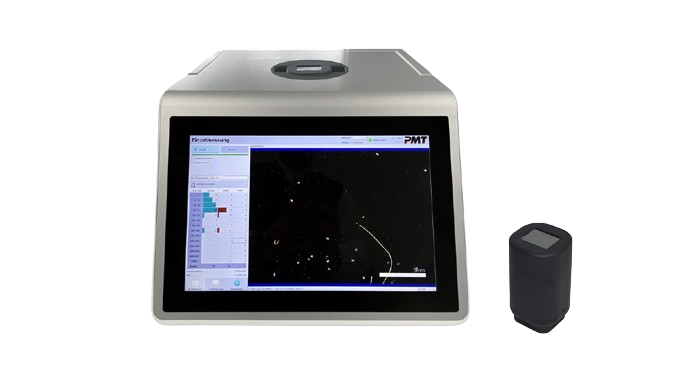

User-Friendly Operation

Designed for ease of use, surface particle counters often feature intuitive interfaces and straightforward operation, reducing the need for extensive training. Additionally, these instruments typically require minimal maintenance, ensuring long-term, reliable performance with low operational costs.

Conclusion

Investing in a surface particle counter can significantly enhance cleanliness control, improve product quality, optimize processes, and ensure compliance with industry standards. As industries continue to demand higher levels of precision and reliability, surface particle counters will remain a vital tool in maintaining product excellence.

By incorporating a surface particle counter into your quality control arsenal, you can achieve cleaner environments, superior product performance, and greater customer satisfaction. Consider our state-of-the-art portable measuring system, the PartSens, as an investment strategy move towards achieving operational excellence and maintaining a competitive edge in your industry.

Follow us for more insights on quality control and the latest advancements in metrology and cleanliness testing.