When working with circular components, considering runout is important. Runout is error introduced into a rotational axis and is caused by and expressed in several different ways.

In this post, we’ll explore what diametral runout is and why understanding it is important.

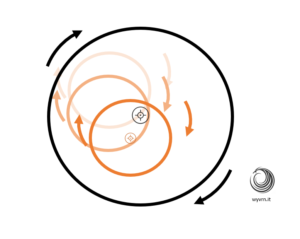

Diametral runout is caused by a rotating part being offset from the center point of rotation for some reason. This offset positioning effectively creates a second axis of rotation that is not inline with the intended center point of rotation.

Imagine sitting at a dinner table with a Lazy Susan in the center of the table. Your dinner guests want a piece of the delicious pie you’ve cooked them, so you place the pie onto the edge of the Lazy Susan and spin it round to them. The pie is not central to the Lazy Susan, so it is rotating differently to it. Put simply, that is diametral runout.

This is an important consideration when looking at round parts, such as turbines and their components. The main reason being that incorrectly positioned parts could cause issues in balance and vibration that reduce efficiency and reliability.

That’s why it is important to both measure and identify which is the cause of error. That way, errors can be resolved, and parts manufactured better.

Our circular geometry range can precisely measure these characteristics, along with a number of others such as planar runout, roundness and eccentricity. This can help eliminate out of tolerance conditions on medium and large components such as turbine and powertrain components and can be conducted quickly and easily on the shop floor.

If you’d like more information on diametral runout, or any of the other geometric conditions we measure, don’t hesitate to contact us. We’re always happy to hear from you!