Our innovative, world leading rotary metrology solutions help improve product quality, producivity and efficiency in a wide variety of industries.

Aerospace

Aerospace manufacturers and MRO (maintenance, repair and overhaul) facilities operate under extreme precision and safety requirements due to the potential for high-risk failures.

Our precision geometry inspection systems verify that parts align with exacting specifications, reducing the risk of error. Additionally, Wyvern’s metrology integration improves quality control processes, allowing for faster, more reliable maintenance and production checks essential in aerospace applications.

The industry demands extremely reliable components to withstand harsh conditions and mission-critical requirements. Any minor contaminant or measurement error can jeopardize mission success and lead to costly or irreparable losses.

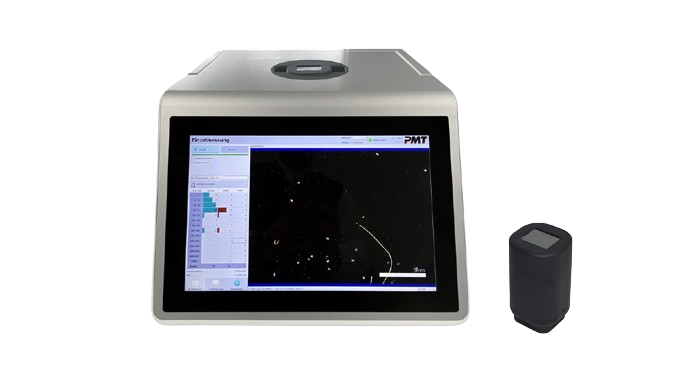

Contaminants and even the smallest measurement inaccuracies can compromise part performance, endanger safety, and cause costly rework or delays. Wyvern’s advanced cleanliness testing solutions detect contaminants at the micro level, ensuring every component meets strict cleanliness standards.

Our cleanliness testing ensures aerospace parts are free from harmful contaminants, enhancing safety and longevity in extreme environments. Our high-precision geometry inspection tools verify exact measurements required for mission-critical reliability. Additionally, Wyvern’s metrology integration enables data traceability and compliance, supporting strict standards and reliable component performance for high-stakes applications.

Day-to-Day Challenges in the Aerospace Industry

Complex Component Design

Aerospace components, such as turbine blades, engine casings, and fuselage parts, often feature intricate geometries. Achieving the required precision while maintaining material integrity is a continuous challenge. Materials like titanium or carbon fiber composites, known for their strength and toughness, are difficult to machine without introducing stress or distortion. Even slight deviations in geometry can lead to performance issues or failure, which are unacceptable in aerospace applications.

Supply Chain Complexities

Managing a global supply chain adds another layer of complexity. Aerospace projects require a consistent flow of high-quality parts from multiple suppliers, often spanning different countries. Delays or quality issues from just one supplier can disrupt production schedules, creating costly setbacks. Ensuring that every part meets the necessary specifications before assembly becomes a top priority.

Tight Tolerances and Quality Assurance

Aerospace manufacturing demands incredibly tight tolerances—often down to microns—due to safety concerns. A tiny imperfection can lead to operational inefficiencies or even catastrophic failure. Day-to-day, manufacturers must perform extensive inspections, adding time to the production process. Traditional inspection methods, which involve frequent repositioning of parts for full inspection, are time-consuming and prone to errors.

Speed vs. Quality

The pressure to reduce lead times is ever-present in aerospace manufacturing. However, increasing production speed without compromising on quality remains a significant challenge. As processes are optimized to push for faster turnaround, the risk of defects or deviations grows, particularly when inspecting complex parts like engine components or structural parts. Manufacturers must strike a balance between speed and precision.

- iMap and GeoInspec systems are used to make aircraft engines run more efficiently as well as enabling them to be built and maintained more quickly.

- Large and cumbersome parts are positioned and moved accurately and quickly using GeoOrdinate

- CMMs operate more accurately and with greater capacity using our Quadrant range

- Angular checks are carried out on Tilt Meters, Resolvers, Gyroscopes, Inclinometers and Guidance systems using LabStandard

Want to know more?

We're always happy to discuss your requirements, potential applications and talk through concepts to help improve productivity and quality