With a range of products designed for demanding environments, Wyvern provides the technology that energy manufacturers need to maintain high standards and optimize productivity.

Energy

Energy manufacturing involves complex processes where accuracy, efficiency, and durability are essential. From power generation components to renewable energy technologies, the industry relies on precise and reliable equipment to meet high safety standards, maximize efficiency, and minimize downtime. Wyvern delivers state-of-the-art rotary measurement and positioning systems designed to address these needs, supporting energy manufacturers in producing high-quality components with confidence.

Day-to-Day Challenges in the Energy Industry

Maintaining High-Precision Standards Amidst Heavy Loads

Energy components, such as turbines and generator rotors, are often large and heavy, making precision measurement challenging. Even slight inaccuracies in alignment or geometry can impact energy efficiency and safety.

Minimizing Downtime and Maintenance Needs

The high demands of energy production make it essential to minimize downtime. Frequent equipment adjustments or repairs can disrupt schedules and lead to costly production delays.

Ensuring Compliance with Safety and Environmental Regulations

Energy manufacturing is subject to strict regulatory standards to ensure both safety and environmental protection. Precise measurement of components is vital for maintaining compliance and avoiding costly penalties.

Addressing the Complexities of Large-Scale Assembly

Assembling and aligning large components, like turbines and generator rotors, requires extreme precision to avoid excessive vibration or wear during operation. Errors in alignment can reduce efficiency and increase the need for frequent maintenance.

Improving Process Efficiency and Reducing Costs

With the push toward renewable energy sources, energy manufacturers must optimize production efficiency to remain competitive. Reducing material waste and improving inspection speed are critical to maintaining cost-effectiveness.

At Wyvern, we are committed to supporting the energy industry with precision measurement solutions that increase efficiency, reduce downtime, and ensure regulatory compliance. With a range of products designed for demanding environments, Wyvern provides the technology that energy manufacturers need to maintain high standards and optimize productivity.

Wyvern's expertise in rotary measurement enables energy manufacturers to achieve the highest standards in quality control and productivity. Our rotary tables and measurement solutions are built to handle the large-scale, heavy-duty components often required in energy production, such as turbines and generators, while maintaining sub-micron precision.

Our range includes specific products designed to meet the diverse needs of the automotive industry:

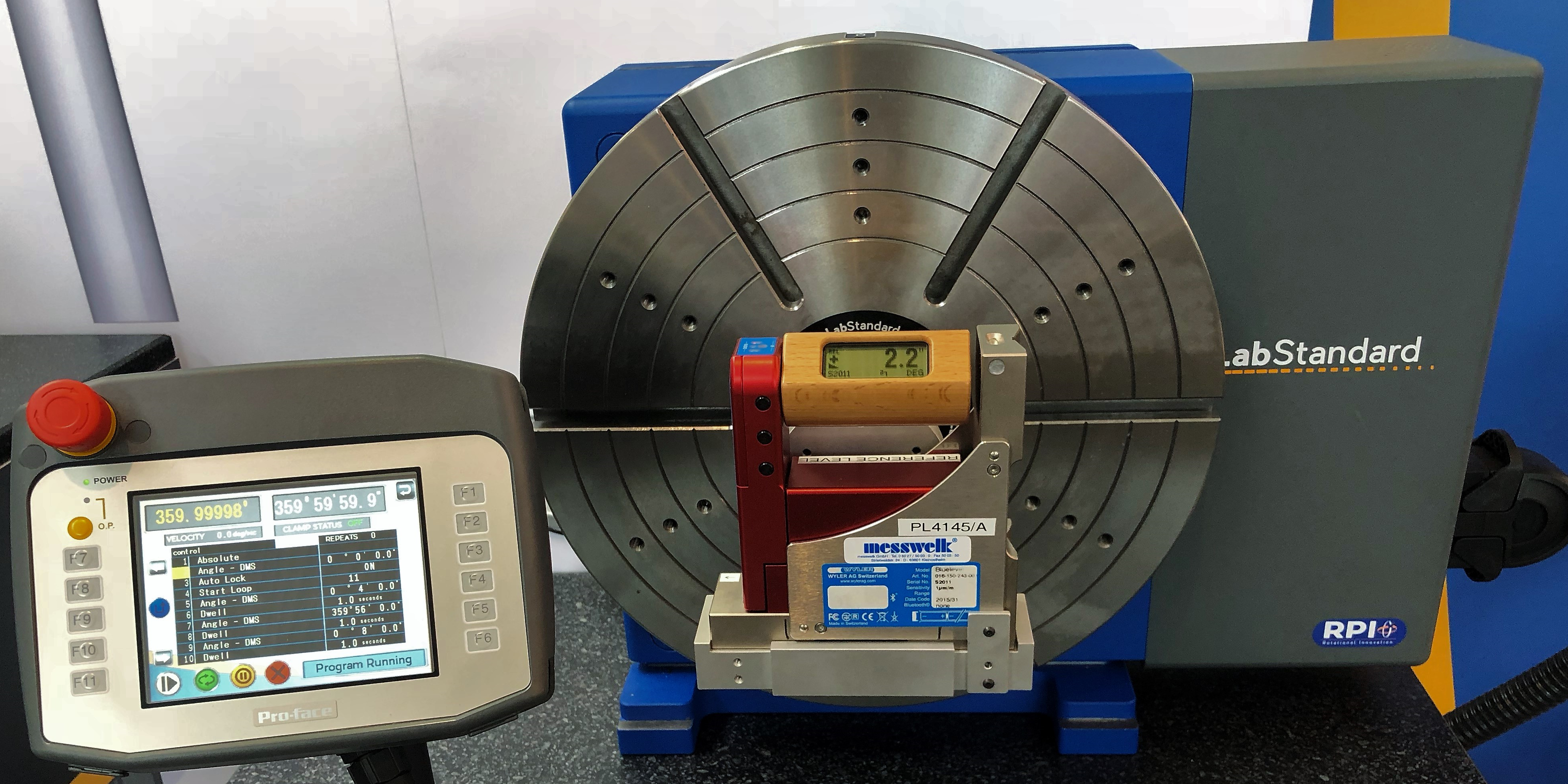

- LabStandard Rotary Tables: The LabStandard series delivers reliable, high-precision performance with incredible stability. Perfect for inspecting gears, shafts, and other rotational components, the LabStandard ensures minimal runout and superior repeatability.

- TruMotion Rotary Tables: For applications requiring ultra-smooth rotation, TruMotion offers exceptional control through air bearing technology. This product is ideal for brake system components and other parts where stability and minimal friction are essential.

- Quadrant Rotary Tables: Designed to increase the capability of Coordinate Measuring Machines (CMMs), Quadrant rotary tables extend the reach of CMM inspections, enabling automotive manufacturers to inspect larger parts with shorter cycle times and greater flexibility.

Want to know more?

We're always happy to discuss your requirements, potential applications and talk through concepts to help improve productivity and quality