Precision Shop Floor Circular Geometry (TIR) Inspection for Small Components

TruMotion is the ideal system for measuring TIR on small and medium parts. With a range of configurations, you can specify and use it exactly as you need it. The robust design is intended for use on the shop floor, whilst offering the impressive levels of performance you'd expect of the Circular Geometry range.

TruMotion at a Glance

Max load: 50Kg/110lb

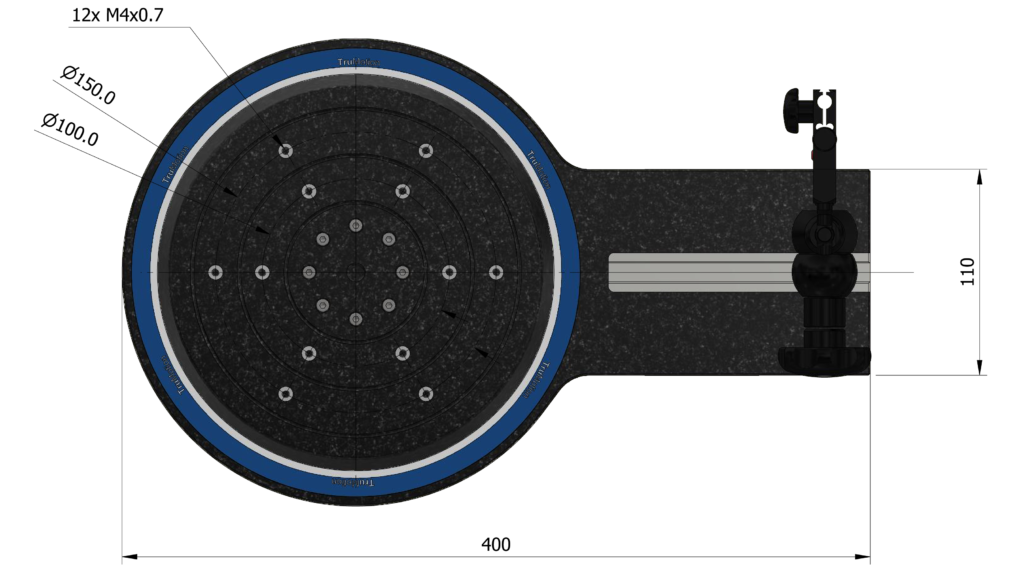

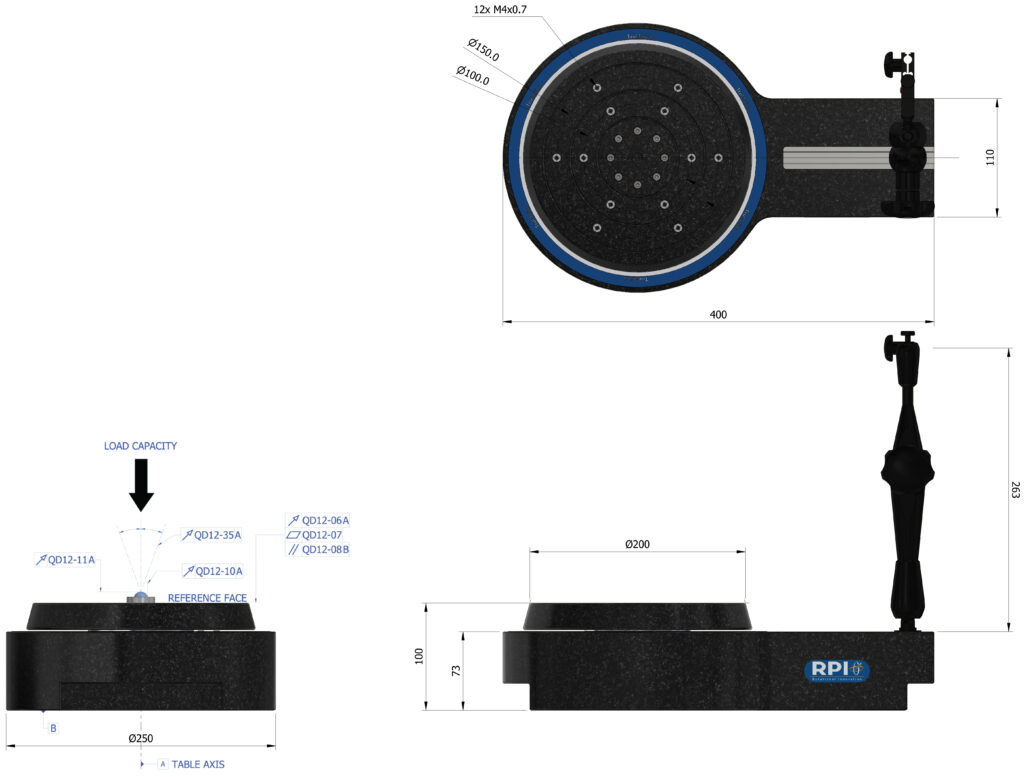

Table top diameter: 200mm (7.9”)

Maximum measurement volume: Ø400mm (17”) x 220mm (8.7”) high

Measurement output: TIR/Runout, One or two simultaneous channels

Part centering: Range of fixtures available, or supply your own to fit drilled and tapped table top finish

Data recording: Digital and manual options available

Integrator features: Optional encoder output for additional positional data

Small Footprint, Portable Design

TruMotion is compact and easy to move when needed. Weighing in at 37lbs, it can be picked up and moved by hand without the need for lifting equipment or any specialist hardware. With TruMotion supporting loads of up to 110lb, its portability isn't at the price of capability.

Affordable and Configurable

TruMotion has a flexible, modular design that provides a range of useful options for the shop floor. Units can be specified with one or two channels of simultaneous measurement, simple outputs or digital, traceable data recording, and a choice of centering fixturing to meet the needs of your parts.

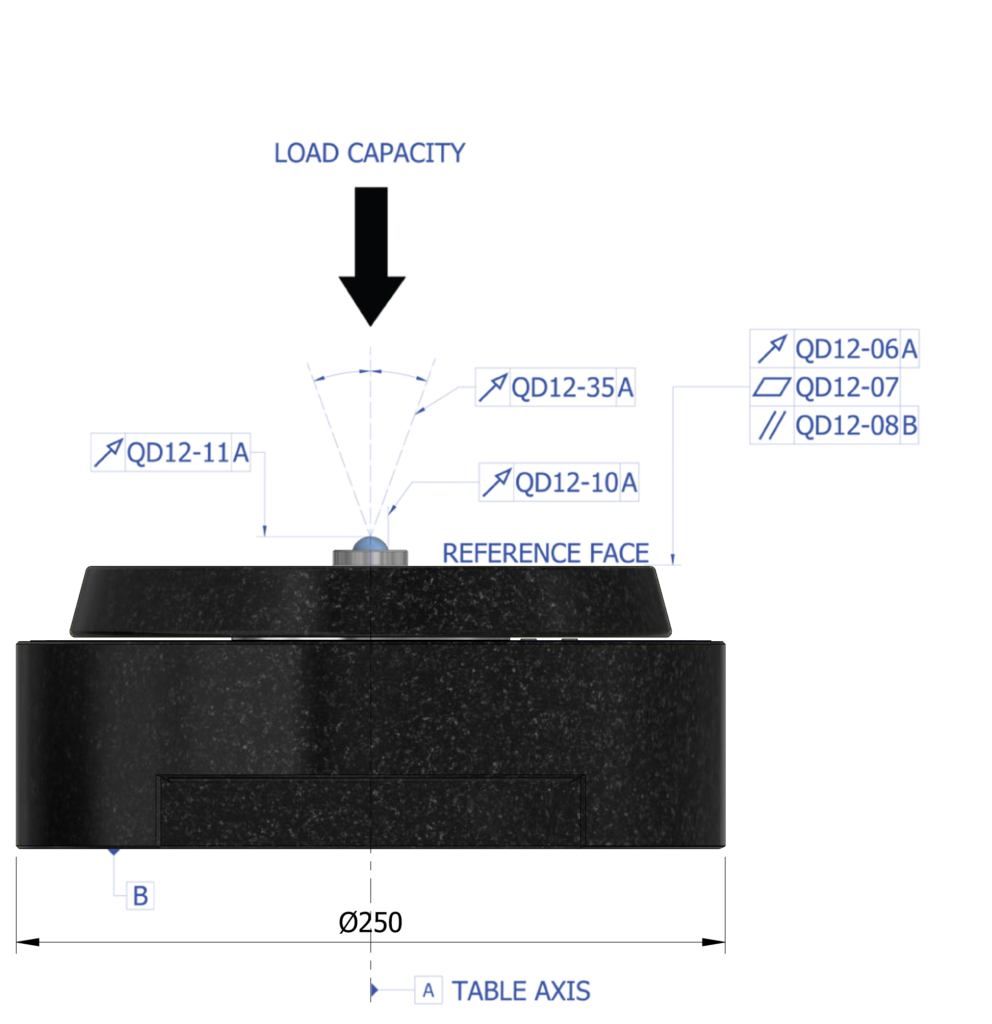

Supreme Precision

TruMotion performs in even harsh environments. With axial and radial runout figures of 0.001mm, it is designed to offer standards room levels of performance in shop floor conditions.

Technical Specifications

- Load capacity (lb): 110

- Rotation Error of Table Top (mm): 0.005

- Flatness of Table Top (mm): 0.005

- Parallelism of Table Top (mm): 0.02

- Radial Runout of Table Top (mm): 0.001

- Axial Runout of Table Top (mm): 0.001

- Coning of Table Axis (Arc Seconds): +/-0.5

- Weight (lbs): 37