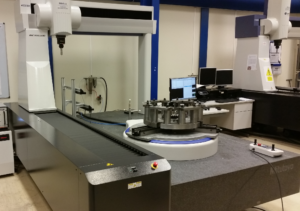

The Quadrant range of rotary tables is used extensively across the world in a multitude of metrology applications.

It’s widely used on virtually every major CMM brand to increase speed, capacity and performance, especially when measuring round, rotating or intricate parts. If you want more background in the benefits of adding a rotary table to a CMM, this short article should help you.

With RPI’s extensive heritage in CMM integration, the range is extensive in its options and provides a solution for virtually any CMM application.

That means that you can select a wide range of configuration options to customize a design to your machine. If you’re not sure what you need, don’t worry – this article will help you decide which Quadrant unit will most suit your requirements!

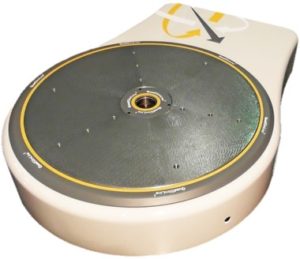

Best for use with an optical scanning head

Choose: QuadProfile

This one is a bit of a no brainer: The QuadProfile is designed to do exactly this! With a fast rotation speed of up to 10rpm, QuadProfile is ideal for scanning applications, allowing the option for rotary motion whilst scanning, enabling the fastest data collection possible.

Despite its high speed, accuracy remains a strong suit of the table, with angular accuracy as great as 2 arc seconds and angular repeatability of 0.5 arc seconds.

Even though the table is small and nimble, it can still support loads of up to 100Kg.

Best for use with long or tall rotating parts like shafts

Choose: QuadDualPurpose

Geometric conditions of long or tall rotating parts can be challenging, because mounting them upright on a CMM can be difficult as a result of the amount of space required to do so. Mounting them horizontally is generally much easier, as it allows you to use the length of the CMM bed to better effect. It can cause problems with access of the underside of the part, though. That means that measurements can be slow and, in some cases, impossible without first repositioning the part.

In this kind of scenario, QuadDualPurpose is the ideal solution. It’s designed to be mounted either horizontally or vertically and can be easily switched between the two if necessary. In vertical position, it means the part can be mounted lengthways and rotated into position, making the underside much more accessible. When mounted vertically, the maximum load moment is 500Nm, meaning that it is flexible for use for a wide range of weights and dimensions.

Best for use when you need flexibility on the bed of the CMM

Choose: QuadSlimline with air flotation base option

If you want to perform tasks on the bed of the CMM without a rotary table, you can configure a QuadSlimline unit to allow you to do just that. By adding the air flotation option, you can simply slide it out of the way when necessary by just pressing a button and moving. This feature can also come in handy for loading and unloading cumbersome parts onto the CMM as an added bonus. You can find out more about the air flotation option here.

Best for integrating into a new CMM

Choose: QuadMatic

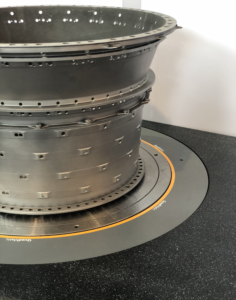

If you’re building a new CMM and want 4th axis capability out of the box, the best option is QuadMatic. It’s designed to be embedded into the granite of the CMM, meaning there’s almost zero footprint into the measurement space of the machine. It’s the most seamless design possible for creating a CMM that’s designed for whatever requirements are thrown at it.

If you’ve just bought a CMM and need to add a rotary axis to it, sadly sinking one into the granite is almost certainly not a feasible option. If that’s the situation you’re in, a QuadSlimline will add the same capacity whilst adding a profile as low as 150mm in height.

Best for use on a small CMM

Choose: QuadProfile, QuadDualPurpose or QuadSlimline 400

If you’ve got a small CMM, we’ve got you covered. Of course, everyone’s definition of “small” is different, and the size of the parts to be measured is a consideration, too. So, the three smallest options available in order from small to large are:

- QuadProfile (225*225*175mm)

- QuadDualPurpose in horizontal configuration (410*535*195mm)

- QuadSlimline 400mm (520*760*150mm)

Note: All dimensions are expressed W x L x H

Best for use on very large or heavy parts

Choose: Large table diameter QuadSlimline

The Quadrant range excels in offering high and large load capacities without sacrificing accuracy, so if you’re trying to measure something particularly large, QuadSlimline is the best choice for you. Its largest configuration consists of a 1,500mm diameter tabletop, which can support loads of up to a remarkable 7,000kg (15,000lb) in mass.

Similarly, a 1,500mm diameter QuadMatic can offer the same load capacity whilst being flush to the granite base of the machine, too.

Summing Up

The Quadrant range is extensive and designed to cover numerous measurement scenarios meaning there’s almost certainly something in the range that fits your needs. If you’re still unsure about which would be best for you, contact us and we’ll be happy to help.