Our innovative, world leading metrology and positioning solutions help improve product quality, producivity and efficiency in a wide variety of industries.

Automotive

Automotive customers use our equipment in a wide range of ways, including using our range of technical cleanliness systems for Quality and Inspection, increasing CMM throughput with the Quadrant range, and sensor testing and positioning using the LabStandard precision rotary table.

CMM & Metrology

CMMs (Coordinate Measurement Machines) benefit from our Quadrant range of rotary tables which improve measurement speed, reduce measurement uncertainty and increase capacity.

From CMM OEMs to end users to service companies, our customers benefit from decades of CMM integration heritage.

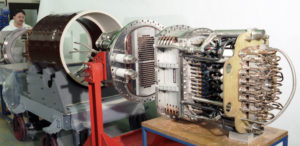

Energy

Our iMap systems are used extensively in the energy sector to maximise product performance. Typically systems are used in steam and gas turbine manufacture at OEM and Tier 1 level as well as in the MRO (Maintenance, Repair and Overhaul) sector.

Because of the high load capacities of our systems, we can offer flexibility and performance even on large components.

Machine Shops

Machine shops benefit from the precise shopfloor TIR inspection capabilities offered by TruMotion.

The LabStandard and LabstandardDUO also offer opportunities to increase performance and quality on turned parts.

Defense and Space

LabStandard and LabStandardDUO help defense and space companies test and improve positioning systems.

Research

The LabStandard, LabStandardDUO, GeoOrdinate and i72 Diamond Standard range of products is used extensively in research and scientific environments

Laboratory

Calibration laboratories benefit from the ultra high performance of LabStandard and i72 Diamond Standard

Heavy Machinery and Plant Equipment

Uptime and reliability are vital for heavy machinery, plant and agricultural equipment. If systems fail in the field, the cost of downtime can be extremely high, and access disruptive. Manufacturers use ParticleView systems to ensure vital equipment is built in the correct conditions.

Airframe

Airframe manufacturers and their supply chain benefit from the ensuring that part surfaces are kept clean using our technical cleanliness range of products, whilst critical subsystem performance is improved by ParticleView.

EV Batteries

Electric Vehicle manufacturing demands more than just precision—it requires trust in every measurement, every surface, and every assembly. To ensure clean, residue-free hairpins, manufacturers are increasingly turning to fluorescence measurement technology — specifically the SITA CleanoSpector and SITA clean line CI systems.

Want to know more?

We're always happy to discuss your requirements, potential applications and talk through concepts to help improve productivity and quality