Our products are used for a wide range of industrial applications. Here's some more information about a few of them:

Turbine Circular Geometry

Aerospace and energy turbines run more efficiently and are built and maintained more quickly when they are measured using our iMap and GeoInspec systems. That's because the systems provide highly accurate shop floor measurement of circular geometry features such as runout, circular flatness, parallelism and roundness.

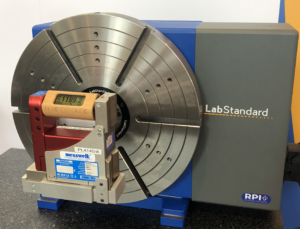

CMM 4th Axis

CMMs are extensively used my many manufacturers. So extensively, in fact, that often there is an inspection bottleneck caused by this. By adding a Quadrant rotary table to a CMM, inspection times are dramatically improved, increasing workflow and productivity.

Sensor Testing

The extremely high precision of our rotary devices means they are ideal for performing tests on tilt sensors, positional sensors, and gyroscopes. We offer solutions that allow one sensor to be tested or many simultaneously for maximum efficiency.

Rotary Axis Calibration

i72 Diamond Standard offers the high levels of accuracy that are required for calibrating rotary axes. It can be used in multiple orientations, too, offering great flexibility.

Precision positioning

If you need to perform rotary precision positioning and indexing, we have a product to suit all requirements. From large to small, all our products offer world leading accuracy and are suitable for the shop floor.

Filmic Contamination Detection

Filmic contamination of surfaces can cause a multitude of quality issues. By using the CleanoSpector, SurfaSpector, or FluoScan systems, any such issues can be quickly and easily detected, enabling finished product quality to be greatly improved.

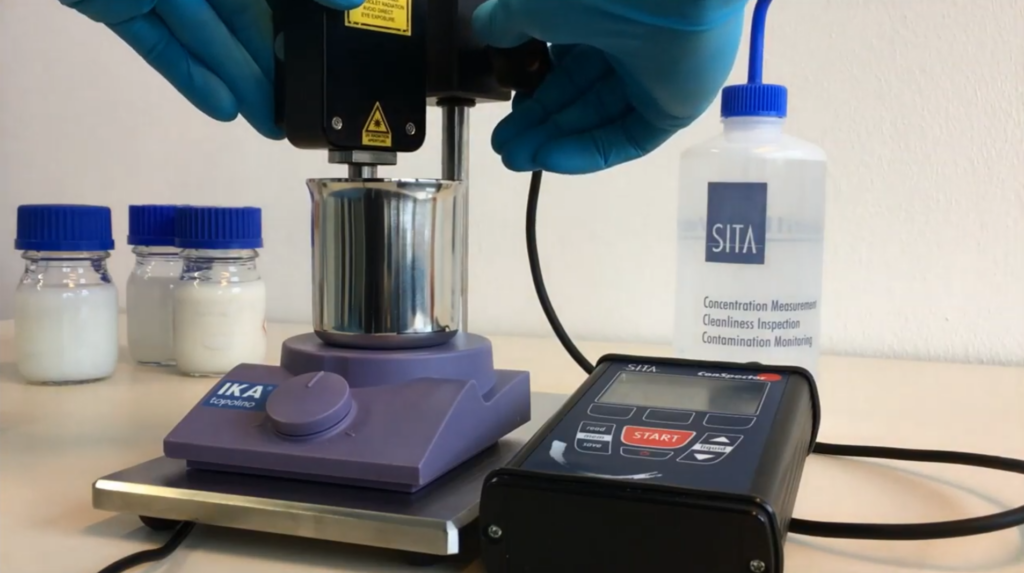

Cleaning bath analysis

If a cleaning bath is not performing as it should, parts may be contaminated causing costly and time consuming quality issues further down the manufacturing process. By analalyzing the performance of cleaning baths, this can be avoided. The DynoTester and ConSpector allow for easy measuring of surfactant levels and the presence of external contaminants such as oil in cleaning bath solutions.

Particle Measurement and Analysis

Particles such as machining residue and external environmental contaminants can cause serious equipment failure on sensitive components such as injectors, lines, and hoses. Using ParticleView or PartSens to check for the presence and nature of such contaminants helps ensure best practice is followed on the shop floor.

Want to know more?

There are many more applications we've worked on, so if you'd like to talk more about your requirements or any of these, don't hesitate to ask.